filmov

tv

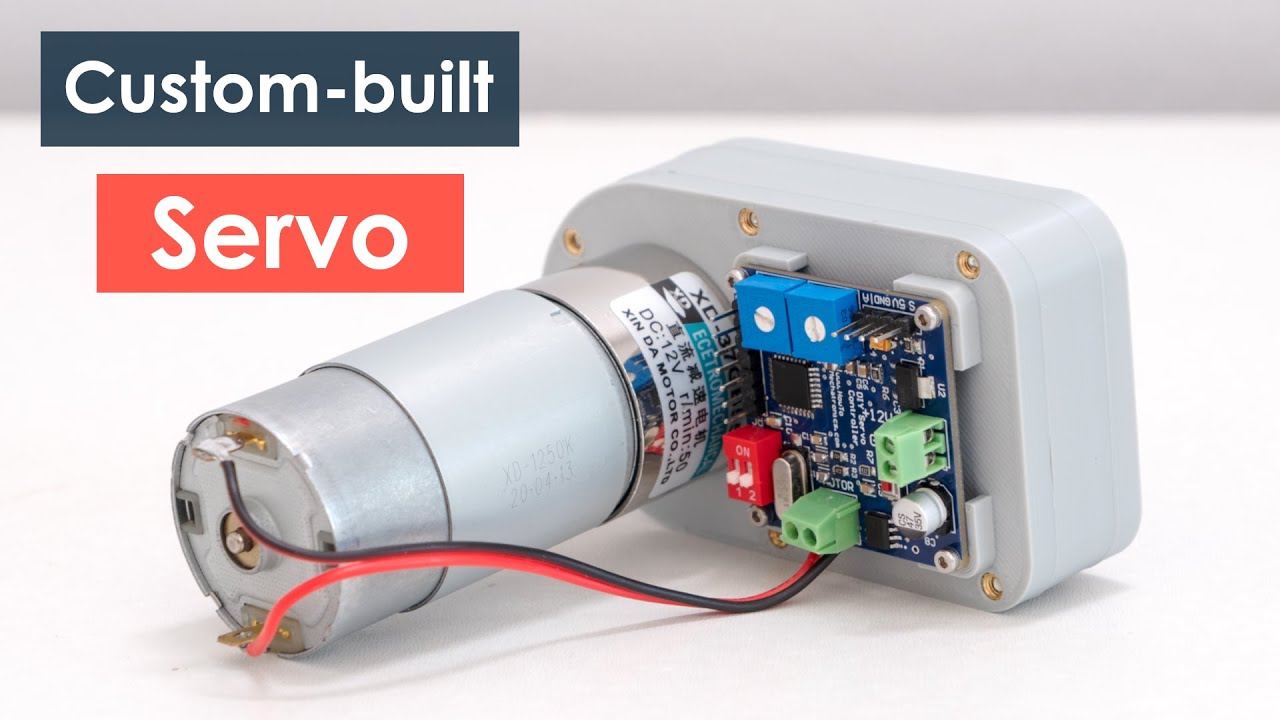

Turn any DC Motor into a Servo Motor

Показать описание

Parts list (check website article for full list, affiliate links):

AliExpress

In this video we will learn how to turn any DC motor into a stand-alone servo motor with a lot of features. Unlike regular servos that have limited motion of 180 or 270 degrees, this one has unlimited range of 360 degrees and in addition to that we have the ability to adjust the range of the rotation to whatever value we need. We can also set a custom center point, we can adjust the responsiveness, it has continuous rotation mode and it can be controlled through an analog input, digital input from a RC receiver and using the serial monitor from our PC.

00:00 Overview

04:18 How a Servo Motor Works

05:08 Closed-loop System

06:50 AS5600 Encoder

08:33 Circuit Diagram

10:59 PCB Design

13:09 3D Design - Gearbox

14:45 Assembling the Servo

17:36 Bootloader and Programming the Servo

19:28 Test

22:18 Code

24:37 Outro

Like my page on Facebook:

Convert Cheap Dc Motor to a Precision Servo #1

DC motor to AC supply

how to RUN an “AC motor” on DC batteries

How To Turn Any Motor Into A Servo Motor (#075)

How to convert regular DC motor in to BLDC drone motor

High speed fan using two dc motors || dc motor hacked #motor #dcmotor #shorts

Build a Custom Servo Motor with a DC Motor

DC motor's speed Controller | Electronics

How To Size Electric Motors for Any Project: A Beginners Guide #085

DC motor forward reverse #shorts

12v Big DC Motor Speed Upgrade with Armature Winding

How to Make 3.7v Dc Motor and Fan Speed Controller Circuit

Dc Motor Overvoltage | 3v motor vs 220v electric

testing a 775 dc motor with homemade cycle dynamo | 775 dc motor || MTC 2.0

How to Make a DC Motor at Home (Cardboard DC Motor)

How DC Motor Works as Generator? | Turn DC Motor Into Electricity Generator

#12v #dcmotor Test in #helicopter or #drone mode

How to make slow DC moter change to fast DC moter #DCMoter #ideas #shortvideos #dcmotorhacks

OVERLOAD DC MOTOR 🔥

Making Powerful Brushless Motor From DC Brushed Motor

How does an Electric Motor work? (DC Motor)

17,000 RPM - Convert 220V Universal Motor from Mixer to DC Motor ( Gazab Speed )

dc motor project #shorts #project

How to convert 220V motor to 12V DC motor amazing tips and idea

Комментарии

0:07:10

0:07:10

0:00:05

0:00:05

0:01:47

0:01:47

0:12:05

0:12:05

0:10:45

0:10:45

0:00:22

0:00:22

0:42:08

0:42:08

0:00:52

0:00:52

0:11:21

0:11:21

0:00:25

0:00:25

0:00:15

0:00:15

0:01:07

0:01:07

0:00:27

0:00:27

0:00:27

0:00:27

0:07:42

0:07:42

0:02:40

0:02:40

0:00:16

0:00:16

0:00:16

0:00:16

0:00:29

0:00:29

0:08:44

0:08:44

0:10:03

0:10:03

0:10:59

0:10:59

0:00:16

0:00:16

0:08:40

0:08:40