filmov

tv

Designing Sheet Metal Parts in Fusion 360

Показать описание

I've had some requests to show the design process I use in Fusion 360 to make bent sheet metal brackets, so that's what we're doing today.

Stuff used in this video:

*This site contains affiliate links for which I may be compensated

Stuff used in this video:

*This site contains affiliate links for which I may be compensated

Proto Tech Tip - 5 Common Sheet Metal Design Mistakes to Avoid

Design Tips for Sheet Metal Bending

Basic guidelines for sheet metal design in 5 mins : Common sheet metal design guidelines and rules

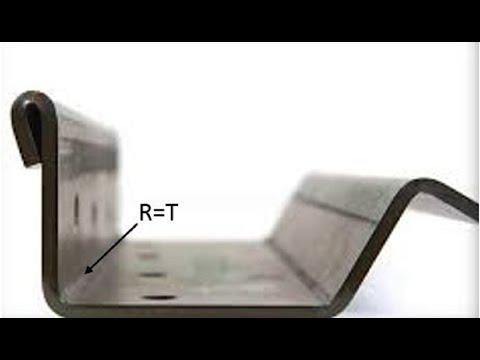

Common sheet metal design Basic rules or guidelines: Minimum Bend Radius

Designing Sheet Metal Parts in Fusion 360

Design guidelines for sheet metal components | Design for manufacturing sheet metal components

SolidWorks Sheet metal Basics

Design sheet metal parts from scratch - BricsCAD Mechanical

Proto Tech Tip - Adding Clearances to Sheet Metal Parts Inside SolidWorks

Proto Tech Tip - Sheet Metal Design Clearances

Intro to SHEET METAL in Fusion 360 - Sheet Metal Beginners Start Here!

What is a K-Factor? | Sheet Metal Bend Allowance Explained

SOLIDWORKS Sheet Metal Modeling Approaches

4 key points for sheet metal bending sequence quality.#pressbrake #sheetmetals

Fusion 360 Sheet Metal for Beginners

Solid Edge Tutorial: Complete and Automated Sheet Metal Design

Intro to SHEET METAL in Fusion 360 - Sheet Metal Beginners Start Here!

Sheet Metal Parts HOW IT'S MADE (B&B Manufacturing

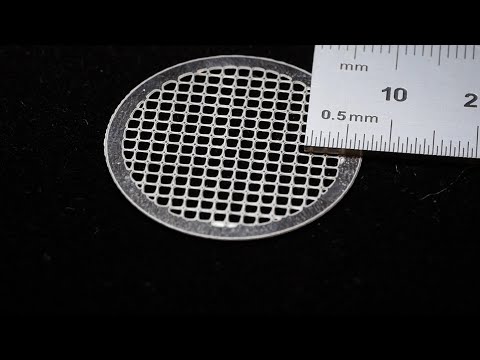

How to make precise sheet metal parts (photochemical machining)

Top Tips for Tab and Slot Design for Sheet Metal Part Assembly - Cutting Corners Episode 3

SolidWorks Sheet metal Exercise Basic Features

Flexible Modeling (FMX) in Sheet Metal Parts - Overview

SolidWorks Sheet Metal Practice Exercises for Beginners - 1

SolidWorks Sheet metal Exercise 129-Sketched Bend and Jog

Комментарии

0:06:00

0:06:00

0:04:49

0:04:49

0:05:54

0:05:54

0:00:30

0:00:30

0:23:27

0:23:27

0:10:08

0:10:08

0:11:35

0:11:35

0:06:05

0:06:05

0:05:13

0:05:13

0:04:44

0:04:44

0:23:51

0:23:51

0:05:44

0:05:44

0:04:59

0:04:59

0:00:52

0:00:52

0:26:21

0:26:21

0:05:01

0:05:01

0:07:35

0:07:35

0:04:50

0:04:50

0:21:56

0:21:56

0:14:21

0:14:21

0:13:42

0:13:42

0:05:37

0:05:37

0:12:39

0:12:39

0:28:00

0:28:00