filmov

tv

What Is a Kaizen Event? (Using Rapid Improvement Events to Become Lean)

Показать описание

OPEX Minute #9. Kaizen Events, Rapid Improvement Event, RIE, Lean Kaizen Events. In this brief video, we talk about kaizen events. What are they? What are the benefits? Presented by EMS Consulting Group:

#opexminute #leanmanufacturingmanagement #kaizen #leanmanufacturing

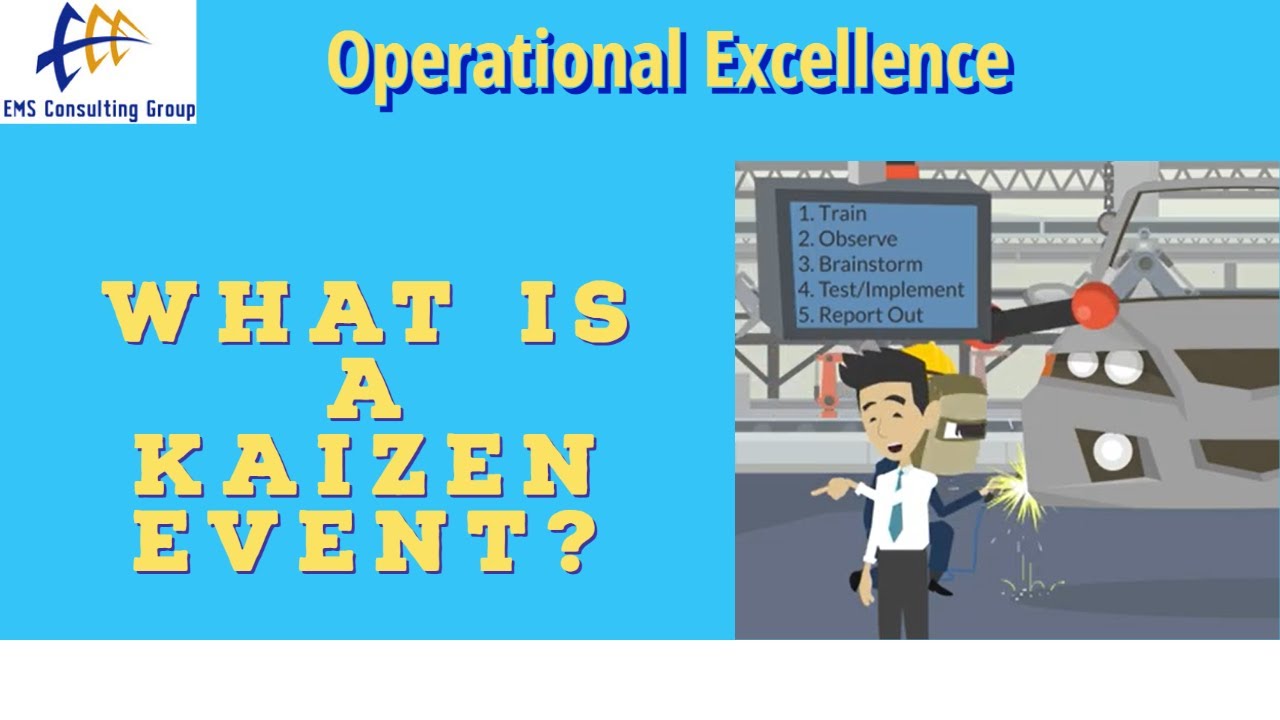

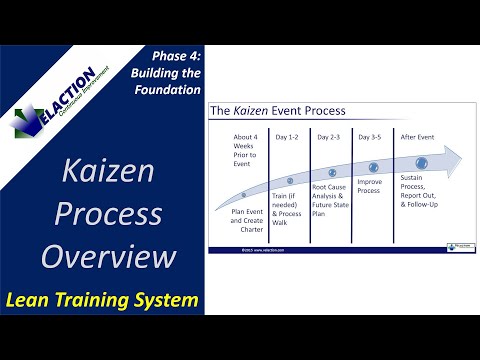

Welcome to today’s edition of the OpEx Minute, presented by EMS Consulting Group. Today we will be talking about Kaizen Events. Kaizen events are very different from the concept of kaizen in general. These events can best be described as Rapid Improvement Events, and they are intended for focused, rapid improvement on a particular process or area.

Why use Kaizen Events? First, kaizen events result in rapid improvement that would otherwise take longer to implement. Next, kaizen events have an excellent return on investment. They can potentially eliminate bottlenecks, reduce or eliminate the need for overtime, and eliminate the need to purchase capital equipment, build new facilities, or expand facilities. Kaizen events are also very flexible; kaizen can be done anywhere on almost any process: it is not limited to the shop floor only. Finally, and perhaps most importantly, kaizen events increase human capital. People learn by doing in kaizen events; they often learn more about processes and their suppliers’ and customers’ needs; and communication improves.

The Kaizen Event Process includes 5 basic steps that the kaizen team goes through. First, there is training- the team learns the kaizen process and improvement tools at its disposal. Next, the team observes and documents the process being improved. Then, the team brainstorms ways to improve the process using what they have learned and observed. The team then acts on its improvement ideas and physically tests and implements the improvements. Finally, the team reports-out and celebrates its achievements.

#opexminute #leanmanufacturingmanagement #kaizen #leanmanufacturing

Welcome to today’s edition of the OpEx Minute, presented by EMS Consulting Group. Today we will be talking about Kaizen Events. Kaizen events are very different from the concept of kaizen in general. These events can best be described as Rapid Improvement Events, and they are intended for focused, rapid improvement on a particular process or area.

Why use Kaizen Events? First, kaizen events result in rapid improvement that would otherwise take longer to implement. Next, kaizen events have an excellent return on investment. They can potentially eliminate bottlenecks, reduce or eliminate the need for overtime, and eliminate the need to purchase capital equipment, build new facilities, or expand facilities. Kaizen events are also very flexible; kaizen can be done anywhere on almost any process: it is not limited to the shop floor only. Finally, and perhaps most importantly, kaizen events increase human capital. People learn by doing in kaizen events; they often learn more about processes and their suppliers’ and customers’ needs; and communication improves.

The Kaizen Event Process includes 5 basic steps that the kaizen team goes through. First, there is training- the team learns the kaizen process and improvement tools at its disposal. Next, the team observes and documents the process being improved. Then, the team brainstorms ways to improve the process using what they have learned and observed. The team then acts on its improvement ideas and physically tests and implements the improvements. Finally, the team reports-out and celebrates its achievements.

0:01:09

0:01:09

0:03:32

0:03:32

0:05:02

0:05:02

0:01:13

0:01:13

0:02:02

0:02:02

0:09:26

0:09:26

0:01:37

0:01:37

0:18:48

0:18:48

0:09:26

0:09:26

0:02:48

0:02:48

0:05:02

0:05:02

0:03:33

0:03:33

0:02:33

0:02:33

0:09:42

0:09:42

0:15:38

0:15:38

0:01:25

0:01:25

0:07:34

0:07:34

0:05:27

0:05:27

0:02:33

0:02:33

0:03:47

0:03:47

0:05:29

0:05:29

0:12:30

0:12:30

0:03:44

0:03:44

0:04:10

0:04:10