filmov

tv

Foam Modelling - How To Make Rapid Prototypes

Показать описание

As part of a college assignment we were asked to experiment with prototyping materials.

While working with foam can be a quick way to make multiple models. We found that by separating the models into multiple parts and then pinning the parts together thus making it modular.

It became an even faster prototyping method thanks to the possibility to combine different parts and make an exponential amount of combinations.

Behance page:

Audio:

Action Bronson Instrumental- Pouches Of Tuna Remix by Donato

In Co-operation with Steve Torfs

#diy #design #make

While working with foam can be a quick way to make multiple models. We found that by separating the models into multiple parts and then pinning the parts together thus making it modular.

It became an even faster prototyping method thanks to the possibility to combine different parts and make an exponential amount of combinations.

Behance page:

Audio:

Action Bronson Instrumental- Pouches Of Tuna Remix by Donato

In Co-operation with Steve Torfs

#diy #design #make

Foam Modelling - How To Make Rapid Prototypes

Product Design Foam Model Making Basics

How to make foam board flexible! #howto #art #lesson #miniatures #flex #bend #shortsart #shorts

Making PU (Polyurethane) foam

Realistic Miniature Stone Walls from Styrofoam #miniature #foam #stone

Foam Core Basics (Cutting, Gluing, other tools)

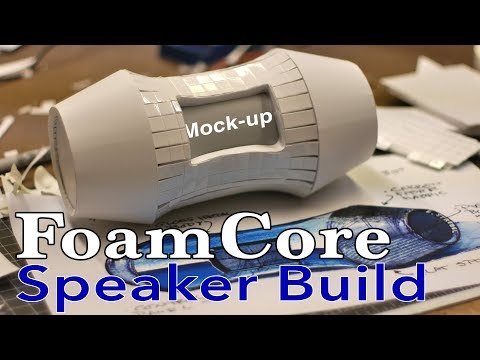

FoamCore model making Design Build with Foam Board: Wireless Bluetooth Speaker Mock up and Wahey-C1

Soft Foam lightweight modelling clay

how to make #papercraft #amazing from#foam #paperflower #ideas #art #love #viralvideos #ytshorts

How to Shape Foam for Perfect Curves Every Time

The EVA Foam Basics | Beginner's Cosplay Tutorial To Armor And Props

Basics: What is that foam you use and where do I get it? (Black Magic Craft Episode 028)

How to Carve Realistic Bricks From Styrofoam Part 1 #diorama #foam #brick

Depron and Modelling Foam Building Techniques

Fast and easy SCULPTING MAGIC with Foam Clay!

How I Made My First Foam Model

hot wire foam cutter

Foam Core Trilogy: Basics, Adv. Basics & Pro Guide FoamBoard model making

Foam Sculpting | How To Carve & Shape | Secret Techniques

easy foam clay DIY ✨ #foamclay #clayart #claydiy #diyideas #easydiyforkids

FoamCore Pro Tutorial Guide Foam Board model making: Compound surface modeling Techniques tips

How to Carve REALISTIC Miniature Stones From FOAM #diy #diorama #miniature

Super Clay ✨ Unboxing 🌸 Foam Clay 🌷Air Dry Clay 💚Soft Clay☘️Modeling Clay #superclay #airdryclay...

DIY Foam clay keychain ✨🐙 #foamclay #claykeychain #airdryclayideas

Комментарии

0:02:33

0:02:33

0:11:08

0:11:08

0:00:26

0:00:26

0:02:20

0:02:20

0:00:52

0:00:52

0:30:00

0:30:00

0:09:00

0:09:00

0:00:51

0:00:51

0:01:01

0:01:01

0:05:43

0:05:43

0:08:29

0:08:29

0:12:10

0:12:10

0:00:54

0:00:54

0:25:46

0:25:46

0:07:45

0:07:45

0:04:50

0:04:50

0:00:17

0:00:17

0:15:57

0:15:57

0:13:03

0:13:03

0:00:11

0:00:11

0:04:09

0:04:09

0:01:01

0:01:01

0:00:19

0:00:19

0:00:16

0:00:16