filmov

tv

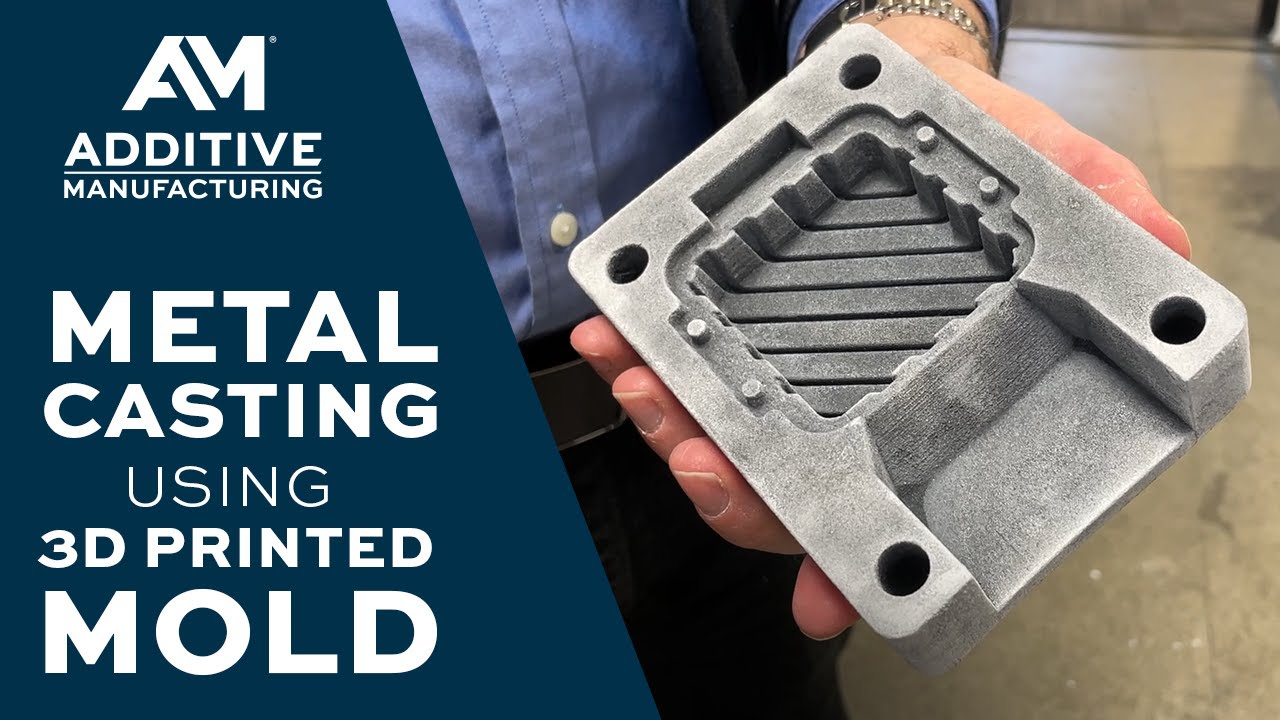

Metal Casting Using 3D Printed Mold and Microwave Furnace: The Foundry Lab Process Explained

Показать описание

Foundry Lab's digital casting process leverages 3D printing in a system able to deliver a casting from a CAD file within one day. In this process, a mold is 3D printed from ceramic. The mold is heated in a microwave furnace to melt the metal into the cast form. This casting method can be performed in any industrial setting; it does not require pouring molten metal or any of the resources typical of a foundry. Prototyping and short-run production of castings are among the applications. Peter Zelinski filmed this description of the process during a visit to Foundry Lab's facility in Fremont, California.

3D Print to Solid Metal, BETTER Than Lost PLA Casting

Metal Casting - Casting a 3D Printed Part 👍SUBSCRIBE!!!👍 #diy #metalcasting

Easy lost PLA metal casting │ How to turn a 3d print into metal │ ASMR

Turning a 3d print into metal - Metal Casting - Lost PLA

Casting Aluminum for the Home from a Simple 3D Print

PolyCast™ - a 3D Printing Filament for Metal Casting

3D Printed Patterns For Metal Casting

Metal Casting Using 3D Printed Mold and Microwave Furnace: The Foundry Lab Process Explained

Turning Raw Silver into a Detailed Owl Portrait

Casting 3D printed charms in sterling silver

Casting Metal Parts into 3D Printed Molds

Amazing 3D Printed Metal Parts!

Learn to Cast Metal Parts from 3D Prints

3D Print to Solid Metal, BEST Way to Prepare Resin Prints for Casting

Turning 3D printed parts into polished aluminum with sand casting #3dprinting #fabrication #metal

Metal Casting with 3d Printed Molds

Ceramic 3D Printing and Metal Casting Combine to Make Complex Parts

Turn your 3D prints into METAL! Full sand casting guide

How to turn a 3D PRINT into METAL │ Lost PLA Metal Casting │ ASMR

PLA vs Poly Cast: Which is better for casting metal.

3D Print to Metal Casting. Higher Level Lost PLA Casting Experiments.

3D Printing Metal: How strong is it?

$150,000 Metal 3D Printer 🤯 #3dprinter #3dprinting #shorts

METAL 3D printed Chainmail🤯

Комментарии

0:11:27

0:11:27

0:01:00

0:01:00

0:08:39

0:08:39

0:09:46

0:09:46

0:11:13

0:11:13

0:04:16

0:04:16

0:04:30

0:04:30

0:01:47

0:01:47

0:15:41

0:15:41

0:00:20

0:00:20

0:02:06

0:02:06

0:00:38

0:00:38

0:11:57

0:11:57

0:12:03

0:12:03

0:00:56

0:00:56

0:04:12

0:04:12

0:01:56

0:01:56

0:06:57

0:06:57

0:13:41

0:13:41

0:12:59

0:12:59

0:17:01

0:17:01

0:01:00

0:01:00

0:00:24

0:00:24

0:00:33

0:00:33