filmov

tv

Do Knifemakers Know How to Heat Treat?

Показать описание

I watched several "How To" heat treating videos to find out if people know what they are doing. I have links below for resources on how to thermal cycle and how to heat to heat treat in a forge if you want to learn more. Or read my book which covers everything.

00:00 Intro

00:19 Real Engineering

08:12 Outdoors55

14:53 Walter Sorrells

20:11 Red Beard Ops

29:16 Bell Blades

32:23 DIYeasycrafts

38:01 Outro and Summary

00:00 Intro

00:19 Real Engineering

08:12 Outdoors55

14:53 Walter Sorrells

20:11 Red Beard Ops

29:16 Bell Blades

32:23 DIYeasycrafts

38:01 Outro and Summary

Do Knifemakers Know How to Heat Treat?

How to start knifemaking without expensive equipment!!

How to peen a knife handle pin #shorts #knifemaking

Avoid getting slapped by broken belts #2x72 #beltgrinder #bladesmith #knifemaker

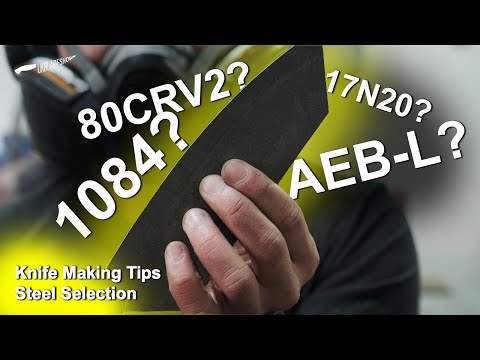

Why 98% of knife makers pick the wrong steel according to a metallurgist

You can see right through this blade! #ultem #clearkydex #knives #knifemaking

Damascus Steel Turned Into Hunting knife #knifemaking #damascus #satisfying

Darkening Blades Using Vinegar #knifemaking

Hardening A Forged Knife Blade In Oil | #Knifemaking #shorts | Custom Knife Making

Knife making with basic tools! #shorts

Is It Possible To Cut Water With A Blade?

what knives do professional chefs use? #shorts

I Forged My Own Chef's Knife

Do You Know Your Knives? #knife #knives ##knifeskills #knifemaking #viral #shorts #short #education

How do I learn?

3 Crazy Old Knives You Can Still Buy Today

He’s a NEW knifemaker?! 🤯

3 Easy Knife Tricks That You Can Try Now #knifetricks #knife

Jeremiah Johnson Classic Bowie Knife #knifemaking #shorts

Making Leather Knife Sheaths #knifemaking #leather

New Bushcraft Knife Sheath | #knifemaking |#shorts #shortvideo

Learn From Knifemakers in Your Machining! | Machining Tips

Big personality, small knives #knifemaker #knife #handmade #diy #knifemaking #edc #everydaycarry

What Makes A Knife Sharp? #knifemaking #knives #forging #survival

Комментарии

0:40:33

0:40:33

0:00:59

0:00:59

0:00:16

0:00:16

0:00:17

0:00:17

0:11:07

0:11:07

0:00:19

0:00:19

0:00:53

0:00:53

0:00:41

0:00:41

0:00:15

0:00:15

0:00:16

0:00:16

0:00:28

0:00:28

0:01:00

0:01:00

0:00:36

0:00:36

0:00:38

0:00:38

0:00:33

0:00:33

0:00:42

0:00:42

0:00:16

0:00:16

0:00:14

0:00:14

0:00:38

0:00:38

0:00:16

0:00:16

0:00:48

0:00:48

0:00:53

0:00:53

0:01:00

0:01:00

0:01:00

0:01:00