filmov

tv

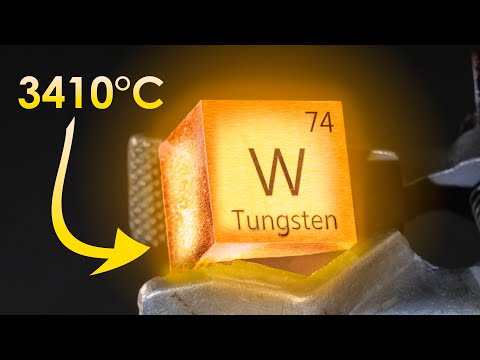

Can You Forge Tungsten?

Показать описание

My name is Alec Steele. I am a blacksmith, amateur machinist and all-round maker of all-things metal. We make videos about making interesting things, learning about craft and appreciating the joy of creativity. Great to have you here following along!

MUSIC:

-signing up at this link supports the show!

- signing up at this link supports the show!

------------------------------------------------

AMAZON AFFILIATE LINKS TO GEAR I LIKE, buying here supports us:

--------------

Can You Forge Tungsten?

Why don't we make a science fiction sword with Tungsten? (W video)

How To Melt THE MOST REFRACTORY METAL on Earth?

Can You Forge Tungsten? The Challenges of Working with the Toughest Metal

How Strong Is Tungsten? Waterjet Cutting Test

Why do I need a Tungsten Carbide Tip on my Hammer?

Tungsten - The MOST REFRACTORY Metal ON EARTH!

Blacksmithing Why Cant You Forge Tungsten Carbide

The Skills Academy are able to provide specialised training in a broad range of welding processes

Can you FORGE ZIRCONIUM?

How Strong Is Tungsten Ring? Hydraulic Press Test!

CAN YOU FORGE A METEORITE!?

The OFFICIAL End of Forged In Fire...

SUPER HARD METAL(Tungsten Carbide)Knife BLADES

Making A Forged Titanium Survival Knife !!

CAN YOU FORGE SOLID GOLD?!?!

What Happens if you MIX ALL The METALS Together?

HIDRAULIC PRESS VS THE HARDEST STONES VS TUNGSTEN

Indian Talwar VS Katana! What Slices Better??

Why You Shouldn't Make Scrap Ingots - Why Scrap Yards Will Say No To Buying Them

Give Me 2 Dozen Old Drills And I'll Make The Sharpest Knife That Will Last 50 Years

Making a KATANA out of Titanium - How I made Katana sword from Titanium

His & Her's Black Celtic Tungsten Carbide Wedding and Engagement Bridal Band Ring Sets

Don't weld with a dirty tungsten #tig #welding

Комментарии

0:16:14

0:16:14

0:01:23

0:01:23

0:17:29

0:17:29

0:04:25

0:04:25

0:06:32

0:06:32

0:06:43

0:06:43

0:05:45

0:05:45

0:14:14

0:14:14

0:00:36

0:00:36

0:12:12

0:12:12

0:13:44

0:13:44

0:16:06

0:16:06

0:08:02

0:08:02

0:00:23

0:00:23

0:10:44

0:10:44

0:11:09

0:11:09

0:19:47

0:19:47

0:07:01

0:07:01

0:00:59

0:00:59

0:02:04

0:02:04

0:19:27

0:19:27

0:42:11

0:42:11

0:00:14

0:00:14

0:00:26

0:00:26