filmov

tv

How Manifold Gauge Works? | Refrigerant Pressure Gauge | Animation | HVAC

Показать описание

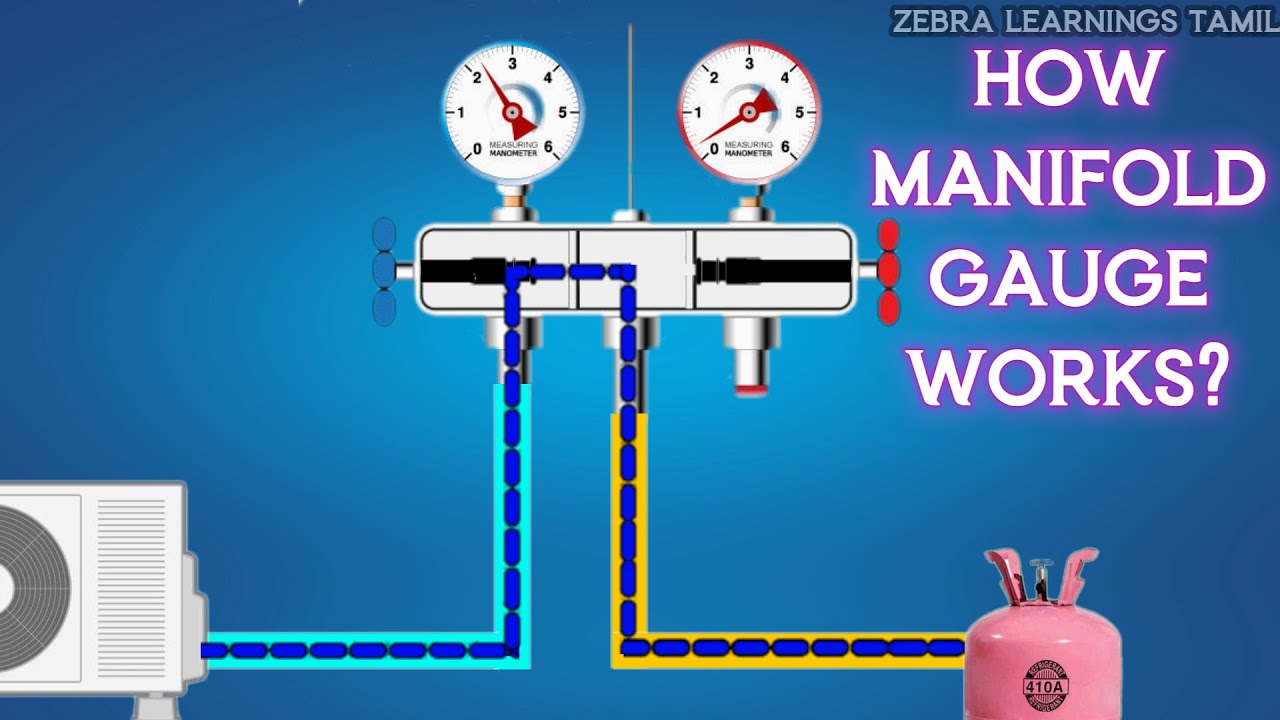

A manifold gauge, also known as a refrigeration gauge or HVAC gauge, is a tool used by HVAC technicians and refrigeration professionals to measure and monitor various parameters of a refrigeration or air conditioning system. It helps them assess the system's performance, diagnose issues, and ensure that the system is operating efficiently. The manifold gauge set consists of several components, including pressure gauges, hoses, and valves.

Here's how a manifold gauge works:

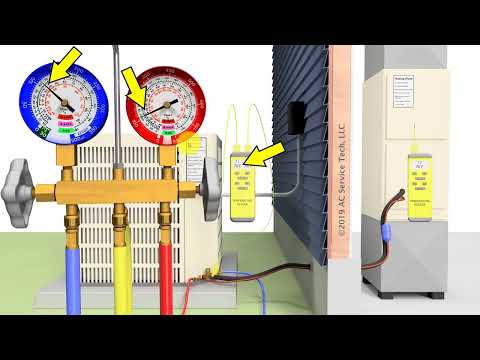

Pressure Gauges: The manifold gauge set typically includes two pressure gauges – a high-pressure gauge and a low-pressure gauge. These gauges display the pressure levels of the refrigerant within the system. The pressure is measured in pounds per square inch (PSI) or sometimes in bar units.

High-Pressure Gauge: This gauge measures the high side pressure of the refrigeration system, which is the pressure of the refrigerant as it exits the compressor and moves toward the condenser.

Low-Pressure Gauge: This gauge measures the low side pressure of the system, which is the pressure of the refrigerant as it enters the evaporator after passing through the expansion valve.

Hoses: The manifold gauge set comes with hoses that connect the pressure gauges to the corresponding pressure ports on the refrigeration system. The hoses are color-coded – blue for the low-pressure side and red for the high-pressure side. This helps prevent mix-ups and ensures correct connections.

Valves and Knobs: The manifold gauge set has several valves and knobs that allow the technician to control the flow of refrigerant and pressure within the system. These valves include:

High-Side Valve: Controls the flow of refrigerant between the high-pressure gauge and the high-pressure side of the system.

Low-Side Valve: Controls the flow of refrigerant between the low-pressure gauge and the low-pressure side of the system.

Service Valve: This valve is used to connect the manifold gauge set to the refrigeration system. It allows the technician to take pressure readings and perform various tasks without releasing refrigerant.

Operation: To use the manifold gauge set, the technician connects the hoses to the pressure ports on the system. They then open the service valves to allow the refrigerant to flow into the gauges. The pressure readings on the gauges give the technician insights into the operating conditions of the system.

If the pressure readings are too high, it might indicate overcharging or a problem with the condenser or expansion valve.

If the pressure readings are too low, it could indicate undercharging, a refrigerant leak, or an issue with the evaporator or compressor.

Temperature Conversion: In addition to pressure readings, some manifold gauge sets also include temperature scales. These scales allow technicians to convert pressure readings into corresponding temperatures for different refrigerants. This can be useful for diagnosing issues and ensuring proper system performance.

Remember that working with refrigerants can be hazardous, and proper training and safety precautions are essential when using a manifold gauge set. It's important to follow manufacturer guidelines and industry best practices to ensure both your safety and the proper functioning of the refrigeration or air conditioning system.

Here's how a manifold gauge works:

Pressure Gauges: The manifold gauge set typically includes two pressure gauges – a high-pressure gauge and a low-pressure gauge. These gauges display the pressure levels of the refrigerant within the system. The pressure is measured in pounds per square inch (PSI) or sometimes in bar units.

High-Pressure Gauge: This gauge measures the high side pressure of the refrigeration system, which is the pressure of the refrigerant as it exits the compressor and moves toward the condenser.

Low-Pressure Gauge: This gauge measures the low side pressure of the system, which is the pressure of the refrigerant as it enters the evaporator after passing through the expansion valve.

Hoses: The manifold gauge set comes with hoses that connect the pressure gauges to the corresponding pressure ports on the refrigeration system. The hoses are color-coded – blue for the low-pressure side and red for the high-pressure side. This helps prevent mix-ups and ensures correct connections.

Valves and Knobs: The manifold gauge set has several valves and knobs that allow the technician to control the flow of refrigerant and pressure within the system. These valves include:

High-Side Valve: Controls the flow of refrigerant between the high-pressure gauge and the high-pressure side of the system.

Low-Side Valve: Controls the flow of refrigerant between the low-pressure gauge and the low-pressure side of the system.

Service Valve: This valve is used to connect the manifold gauge set to the refrigeration system. It allows the technician to take pressure readings and perform various tasks without releasing refrigerant.

Operation: To use the manifold gauge set, the technician connects the hoses to the pressure ports on the system. They then open the service valves to allow the refrigerant to flow into the gauges. The pressure readings on the gauges give the technician insights into the operating conditions of the system.

If the pressure readings are too high, it might indicate overcharging or a problem with the condenser or expansion valve.

If the pressure readings are too low, it could indicate undercharging, a refrigerant leak, or an issue with the evaporator or compressor.

Temperature Conversion: In addition to pressure readings, some manifold gauge sets also include temperature scales. These scales allow technicians to convert pressure readings into corresponding temperatures for different refrigerants. This can be useful for diagnosing issues and ensuring proper system performance.

Remember that working with refrigerants can be hazardous, and proper training and safety precautions are essential when using a manifold gauge set. It's important to follow manufacturer guidelines and industry best practices to ensure both your safety and the proper functioning of the refrigeration or air conditioning system.

Комментарии

0:03:52

0:03:52

0:10:53

0:10:53

0:06:35

0:06:35

0:20:03

0:20:03

0:09:17

0:09:17

0:05:16

0:05:16

0:26:34

0:26:34

0:11:51

0:11:51

0:05:18

0:05:18

0:02:17

0:02:17

0:13:09

0:13:09

0:09:25

0:09:25

0:01:31

0:01:31

0:21:45

0:21:45

0:23:49

0:23:49

0:04:02

0:04:02

0:16:14

0:16:14

0:01:43

0:01:43

0:12:19

0:12:19

0:11:45

0:11:45

0:12:22

0:12:22

0:24:40

0:24:40

0:15:57

0:15:57

0:23:13

0:23:13