filmov

tv

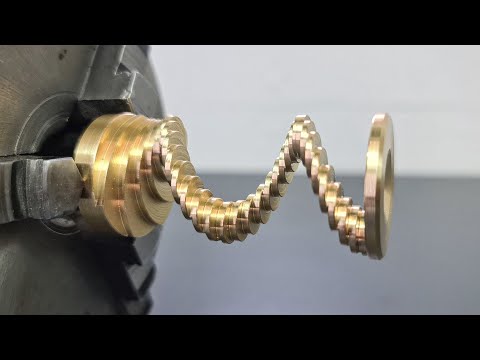

Genius Workholding + Tab Technique | DNM 5700L | DN Solutions

Показать описание

CNC Machine shop genius. Here is some advanced techniques to take your fixturing to the highest level.

Help us fund FREE Education by purchasing tools seen in our videos here:

FREE CNC Machining Academy:

FREE Aerospace Academy:

___

___

FREE CNC Machining Academy. Join the Revolution:

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

___

___

THANK YOU to our Partners who make this content possible:

#CNC #Machining #Machinist

Help us fund FREE Education by purchasing tools seen in our videos here:

FREE CNC Machining Academy:

FREE Aerospace Academy:

___

___

FREE CNC Machining Academy. Join the Revolution:

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

___

___

THANK YOU to our Partners who make this content possible:

#CNC #Machining #Machinist

Genius Workholding + Tab Technique | DNM 5700L | DN Solutions

Increase Efficiency with the TABS Fixturing Technique | DNM 5700 | DN Solutions

How To Machine A Complex Part 600% Faster Using Trick Techniques

Explication des tabs

Secret Process to Machining DIFFICULT Hard to Hold Parts | DVF 5000 | DN Solutions

How Does 5-axis Workholding Work?

Clamps falling down?

CNC Machining Strategies to Remove Chatter | DNM 5700L | DN Solutions

Making a Crazy Part on the Lathe - Manual Machining

Complex 5 Axis Part Holding On By a Thread

Second Operation CNC Machining

Creating Custom Fixture on the DNM 5700L CNC Mill | DN Solutions

DUMB Engineering Design Makes This Part IMPOSSIBLE To Make

Holding Complex Parts - Made Simple!

THIS JOB SUCKS… The Other Machinists Won’t Teach Me…

Tormach Machinist Tip - Basic Steps to Indicate (Square) a Vise

TITAN FUNDAMENTALS: Simulating Your CNC Program

Aerospace Machining parts

Not Square? No PROBLEM - QUADRALLEL

Raptor Dovetail Workholding #raptorworkholding

Setting up a Pyramid Fixture on our DVF 5000 5-Axis CNC Machine | DN Solutions

If You Master The Art of CNC Fixturing, You Will Make A LOT OF MONEY in This Industry

If You Have A Stuck Tap And You Fear Breaking It. Watch This Video.

A Craftsman's Legacy | The Joiner | Woodworking

Комментарии

0:03:29

0:03:29

0:02:28

0:02:28

0:11:41

0:11:41

0:04:53

0:04:53

0:09:27

0:09:27

0:00:07

0:00:07

0:00:15

0:00:15

0:07:55

0:07:55

0:04:15

0:04:15

0:00:59

0:00:59

0:18:19

0:18:19

0:05:53

0:05:53

0:07:37

0:07:37

0:06:19

0:06:19

0:05:55

0:05:55

0:06:45

0:06:45

0:02:19

0:02:19

0:00:19

0:00:19

0:06:50

0:06:50

0:05:37

0:05:37

0:02:56

0:02:56

0:07:21

0:07:21

0:04:03

0:04:03

0:28:20

0:28:20