filmov

tv

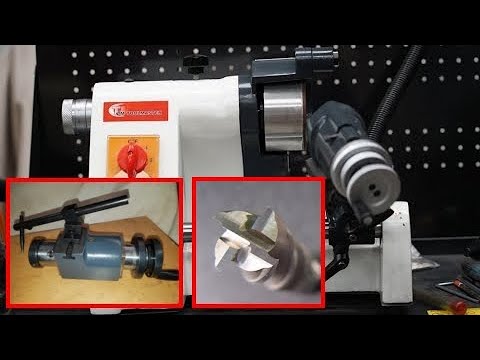

End Mill Sharpening Guide : Universal Tool & Cutter Grinder AKA D Bit Grinder

Показать описание

Complete guide to sharpening end mills on the D-bit grinder. Covers sharpening the end cutting edges and the flutes using the flute grinding attachment that the D-bit grinder usually comes with. These grinders are clones of the original Deckel grinder and are sold around the world with different model numbers such as PP-U3, TM-U3, U2, U3 etc.

End Mill Sharpening Guide : Universal Tool & Cutter Grinder AKA D Bit Grinder

CUTTERMASTER Professional End Mill Sharpener

How to Sharpen an End Mill Cutter

Sharpening End Mills At Home (probably?) - Acute Tool Sharpener Conclusion

Sharpening End Mills On The Lathe

How to use universal tool grinding machine 600F grinding big end mill #machine #mrcm #tool #grinder

Endmill Flute Sharpening

How end mill sharpener work?Let us show you!

EMS414 End Mill Sharpener Beginners Guide

Sharpening the Flutes on a Milling Cutter

End Mill Sharpener Easy Operate, High Accurate

Sharpen end mills

A end mill sharpener can help you save the cost, one machine as 60 pcs of the end mills’ cost.

Almost essential in any CNC shop the EMG 12 End Mill Grinder

end mill sharpening for us poor folks.

How to Sharpen End Mills

Universal cutter grinder MR-U3 to grinding end mill

End mill sharpening fixture.

simple end mill bit sharpening

How to grind the end mill? Use a end mill sharpener, easy work, fast and accurate

MRCM UNIVERSAL CUTTER GRINDER MR-U3

End mill sharpener can for end mill side edge 🎉🎉🎉#machine #mrcm #manufacturer #tool #diy #endmill...

Use 600F universal tool grinder to sharpen big end mill

MRCM Ball nose end mill sharpener #toolgrinder

Комментарии

0:00:20

0:00:20

0:01:48

0:01:48

0:28:03

0:28:03

0:10:29

0:10:29

0:00:18

0:00:18

0:31:01

0:31:01

0:00:16

0:00:16

0:04:00

0:04:00

0:02:53

0:02:53

0:00:11

0:00:11

0:00:31

0:00:31

0:00:14

0:00:14

0:09:10

0:09:10

0:05:23

0:05:23

0:11:55

0:11:55

0:00:16

0:00:16

0:07:55

0:07:55

0:16:21

0:16:21

0:00:16

0:00:16

0:08:22

0:08:22

0:00:09

0:00:09

0:00:07

0:00:07

0:00:13

0:00:13