filmov

tv

Strain Gauge 4 - Temperature Correction.MP4

Показать описание

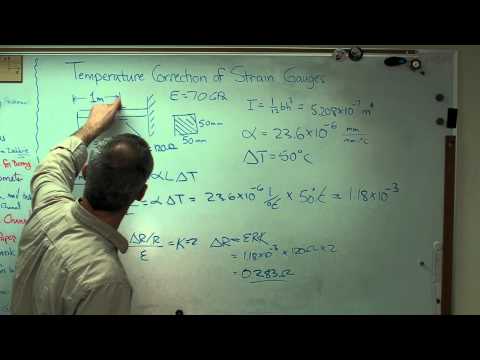

This clip shows how to correctly measure bending strain in a beam even if there is a temperature change. I show how to use two gauges in a half bridge configuration and give some sample calculations.

Strain Gauge 4 - Temperature Correction.MP4

The Effect of Temperature on Strain Gauge Sensors

Temperature Compensation of Strain Gage Sensors, Is it Possible? (4 Min. Case Study)

Lec 9 1 II Temperature Compensation Techniques for Strain Gauge

Strain Measurement

The Ingenious Design of Strain Gauges

Temperature Sensitivity Of Quarter Bridge Strain Gauges

Strain Gauge 101 - Learn the basics of how they're used

Lecture 4: Temperature compensation for strain gauges

Extreme temperature strain gage advancement

Strain gage Temperature Compensation with Dummy gage

How to Select a Strain Gage – Self Temperature Compensation (STC) - The Lazy S.

KISS Principle for Attaching Leads to High Temperature Strain Gages

High Temperature Strain Gage Calibration

Strain gage for measuring Thermal Expansion Coefficient

Half Bridge – Thermal Compensating Gage.

StrainSensingCompensation

Strain Gage Lead wire temperature effect

Encapsulated Weldable Strain Gage for high temperature

Wheatstone Bridge with strain gauge explained

temperature compensation methode in strain guage

High Temperature Calibration of Strain Gage

Electronic Basics #33: Strain Gauge/Load Cell and how to use them to measure weight

Compensating For Thermal Expansion in Standard Wheatstone Bridge Configuration

Комментарии

0:02:43

0:02:43

0:04:08

0:04:08

0:13:39

0:13:39

0:09:30

0:09:30

0:19:40

0:19:40

0:01:11

0:01:11

0:01:20

0:01:20

0:12:17

0:12:17

0:01:45

0:01:45

0:09:40

0:09:40

0:13:15

0:13:15

0:07:14

0:07:14

0:01:54

0:01:54

0:02:36

0:02:36

0:03:42

0:03:42

0:10:00

0:10:00

0:01:23

0:01:23

0:04:14

0:04:14

0:07:12

0:07:12

0:09:22

0:09:22

0:04:11

0:04:11

0:07:45

0:07:45

0:09:38

0:09:38