filmov

tv

What is Sensor Calibration and Why is it Important?

Показать описание

=============================

✅ Check out the full blog post over at

=============================

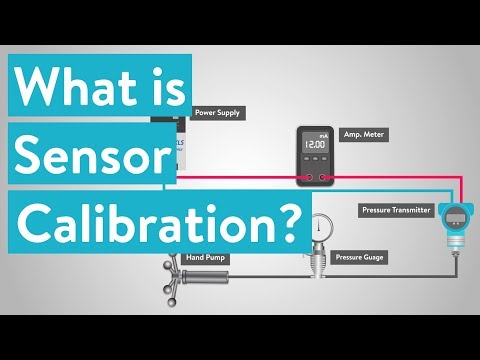

When engineers design modern process plants, they specify sensors to measure important process variables, such as flow, level, pressure, and temperature.

These measurements are used to help the process control system adjust the valves, pumps and other actuators in the plant to maintain the proper values of these quantities and to ensure safe operation.

So how does a plant maintain the operation of these sensors to guarantee that the actual value of the process is sensed and passed to the control system?

In this video, you will learn that the answer to that question is: “Sensor Calibration”.

Sensor calibration is an adjustment or set of adjustments performed on a sensor or instrument to make that instrument function as accurately, or error-free, as possible.

An error is simply the algebraic difference between the indication and the actual value of the measured variable.

Errors in sensor measurement can be caused by many factors.

First, the instrument may not have a proper zero reference.

Modern sensors and transmitters are electronic devices, and the reference voltage, or signal, may drift over time due to temperature, pressure, or change in ambient conditions.

Second, the sensor’s range may shift due to the same conditions just noted, or perhaps the operating range of the process has changed.

For example, a process may currently operate in the range of 0 to 200 pounds per square inch, but changes in operation will require it to run in the range of 0 to 500 pounds per square inch.

Third, error in sensor measurement may occur because of mechanical wear, or damage. Usually, this type of error will require repair or replacement of the device.

Errors are not desirable since the control system will not have accurate data from which to make control decisions, such as adjusting the output of a control valve or setting the speed of a feed pump.

If the calibration is too far from the accurate process conditions, process safety may be jeopardized.

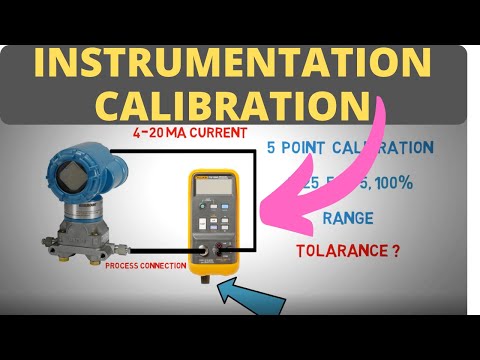

To perform an “as-found” check, an accurate and precise instrument is used to develop process signals corresponding to 0%, 25%, 50%, 75% and 100% of the process range of the transmitter.

The corresponding transmitter output, in milliamps, is observed and recorded. This is called a “5-point” check.

Then, in order to check for hysteresis, a phenomenon whereby the sensor output for a process value is different going 'downscale' as it is going 'upscale', the output signals corresponding to 100%, 75%, 50%, 25%, and 0% in order are recorded.

The deviations at each checkpoint are calculated and compared to the deviation maximum allowed for the device. If the deviation is greater than the maximum allowed, then a full calibration is performed. If the deviation is less than the maximum allowed, then a sensor calibration is not required.

If we have an analog transmitter, we must adjust zero and span to reduce the measurement error. With an analog transmitter, there is a ZERO and SPAN adjustment on the transmitter itself.

Zero adjustment is made to move the output to exactly 4 milliamps when a 0% process measurement is applied to the transmitter, and the Span adjustment is made to move the output to exactly 20 milliamps when a 100% process measurement is applied.

Unfortunately, with analog transmitters, the zero and span adjustments are interactive; that is, adjusting one moves the other. Therefore, the calibration is an iterative process to set zero and span, but only 2 to 3 iterations are usually required.

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

=============================

=============================

Комментарии