filmov

tv

Instrumentation Calibration - [An Introduction]

Показать описание

In this video I introduce you to instrumentation calibration. I discuss why calibration is so important in industry. Go over instrumentation calibration process and also talk about how often instrumentation is calibrated.

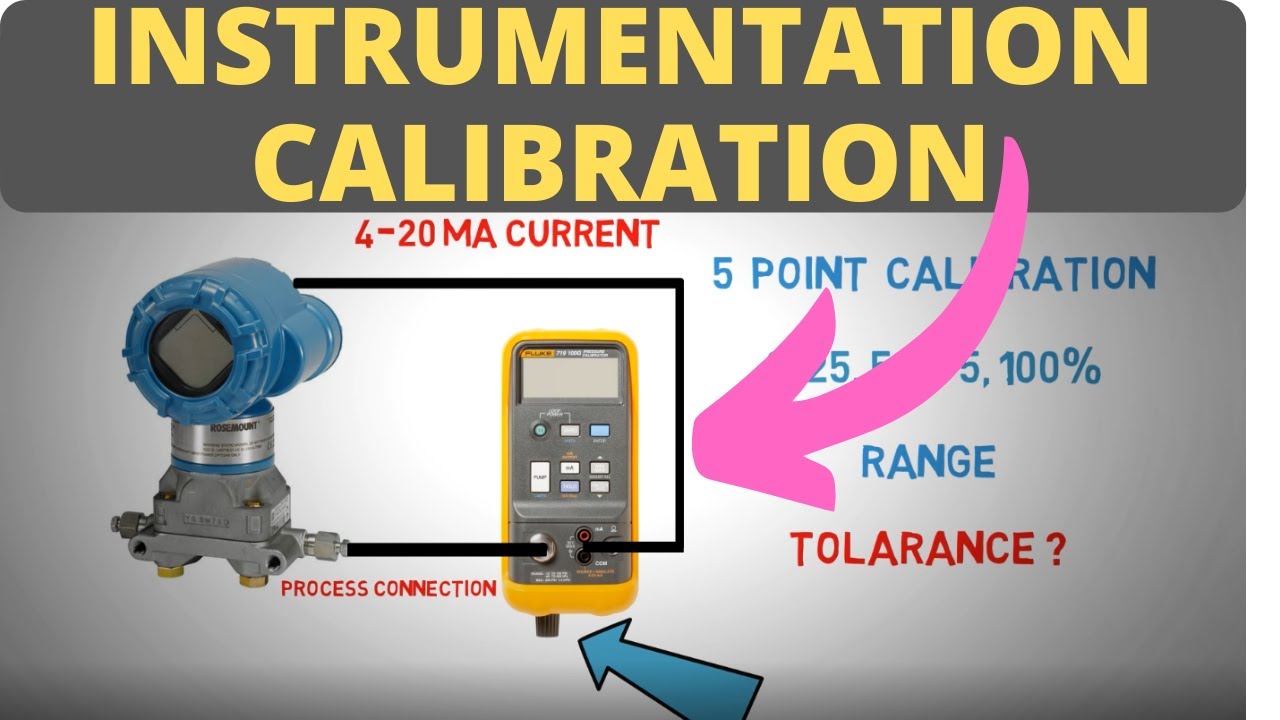

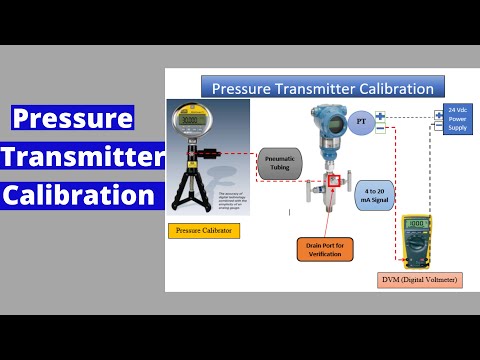

As we learnt in the transmitter lesson, Instrumentation is measuring the real-life conditions of a plant’s process. Lets take an electronic pressure transmitter that is measuring the pressure inside a vessel. The instrument is connected to the sites control system via a 4-20mA current signal. The control system then gives a readout to our control room operator so he can monitor and know the exact state of the plant.

But how does the control room operator know that the pressure he is seeing on his screen is the exact pressure that is in the vessel, what makes him trust that this instrumentation is accurate and reliable?

In many process industries the precision of the process variables instrumentation is measuring is extremely important, for quality of the product that is being created, The safety of people and equipment and for the profitability of the business.

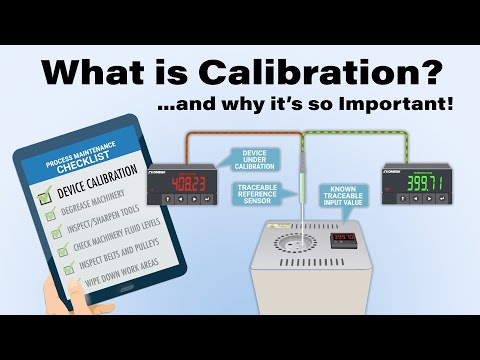

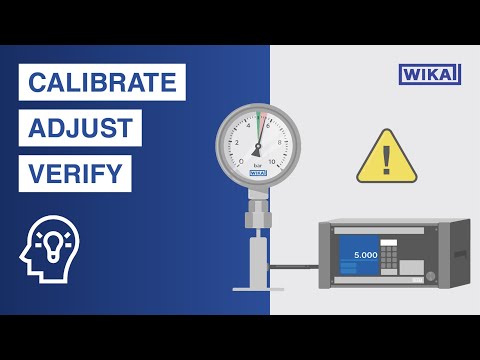

Regular calibration of the Instrumentation is what gives us this confidence. Calibration is the process of comparing plant instrumentation to a known quantity to check for the instrumentation’s accuracy. Adjustments are then made if the accuracy of the equipment is out of its allowed tolerance. The known quantity Instrumentation is checked against is usually in the form of test equipment that is regularly calibrated to a high degree of accuracy.

Test equipment calibration is often carried out at dedicated calibration labs that will be accredited to certain standards depending on the country you are operating in. Here in UK UKAS is an accreditation body that will ensure a calibration lab is certifying its equipment to the appropriate standard.

▶▶Check out brilliant T-shirts / Merch at my store:

▶▶Check out my website for more articles on Instrumentation:

As we learnt in the transmitter lesson, Instrumentation is measuring the real-life conditions of a plant’s process. Lets take an electronic pressure transmitter that is measuring the pressure inside a vessel. The instrument is connected to the sites control system via a 4-20mA current signal. The control system then gives a readout to our control room operator so he can monitor and know the exact state of the plant.

But how does the control room operator know that the pressure he is seeing on his screen is the exact pressure that is in the vessel, what makes him trust that this instrumentation is accurate and reliable?

In many process industries the precision of the process variables instrumentation is measuring is extremely important, for quality of the product that is being created, The safety of people and equipment and for the profitability of the business.

Regular calibration of the Instrumentation is what gives us this confidence. Calibration is the process of comparing plant instrumentation to a known quantity to check for the instrumentation’s accuracy. Adjustments are then made if the accuracy of the equipment is out of its allowed tolerance. The known quantity Instrumentation is checked against is usually in the form of test equipment that is regularly calibrated to a high degree of accuracy.

Test equipment calibration is often carried out at dedicated calibration labs that will be accredited to certain standards depending on the country you are operating in. Here in UK UKAS is an accreditation body that will ensure a calibration lab is certifying its equipment to the appropriate standard.

▶▶Check out brilliant T-shirts / Merch at my store:

▶▶Check out my website for more articles on Instrumentation:

Комментарии

0:05:42

0:05:42

0:02:44

0:02:44

0:06:35

0:06:35

0:02:05

0:02:05

0:14:22

0:14:22

0:03:06

0:03:06

0:11:51

0:11:51

0:03:47

0:03:47

0:17:31

0:17:31

0:02:35

0:02:35

0:00:59

0:00:59

0:06:48

0:06:48

0:05:51

0:05:51

0:08:02

0:08:02

0:06:07

0:06:07

0:00:29

0:00:29

0:04:20

0:04:20

0:00:15

0:00:15

0:01:00

0:01:00

0:01:00

0:01:00

0:51:56

0:51:56

0:02:51

0:02:51

0:04:47

0:04:47

0:03:39

0:03:39