filmov

tv

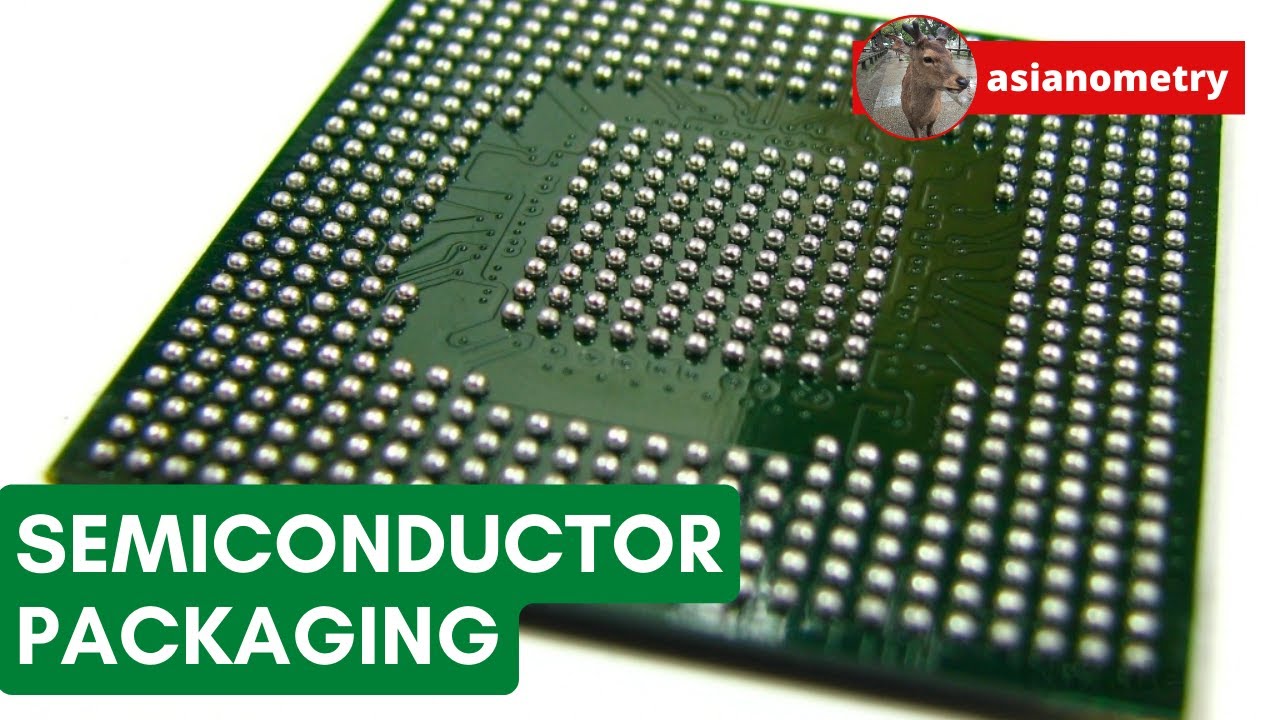

A Brief History of Semiconductor Packaging

Показать описание

Links:

A Brief History of Semiconductor Packaging

The EVOLUTION of Semiconductor Manufacturing: A Brief History! | VectorVest

The race for semiconductor supremacy | FT Film

‘Semiconductor Manufacturing Process’ Explained | 'All About Semiconductor' by Samsung Sem...

Transistors - The Invention That Changed The World

What Is A Semiconductor?

A Brief History of Dynex Semiconductor.

Semiconductor production process explained

India’s Game-Changing Move in Semiconductor Technology Shocks the World

Evolution of Semiconductor || History of semiconductor

The Birth of Taiwan’s Semiconductor Industry

Travel back in time: Semiconductor development history at Bosch

History of semiconductor

A brief history of the deverticalization of the world's semiconductor landscape (1st half)

Silicon, Semiconductors, & Solar Cells: Crash Course Engineering #22

The Flawed Assumptions Behind China’s Big Semiconductor Fund

The World of Microchips: Inside the Semiconductor Industry

The History of the Semiconductor Photomask

Things You Didn’t Know About Semiconductor | 'Semiconductor Dictionary' by Samsung Semicon...

TSMC founder Morris Chang on the evolution of the semiconductor industry

The US Military's Semiconductor Buying Problem

Japan’s Legendary Semiconductor Breakthrough

India’s Lost Semiconductor History | Can India Become Semiconductor Superpower

History of IC | Worlds first IC #vlsi #semiconductor #technology

Комментарии

0:18:31

0:18:31

0:08:24

0:08:24

0:28:32

0:28:32

0:07:44

0:07:44

0:08:12

0:08:12

0:04:46

0:04:46

0:03:46

0:03:46

0:02:05

0:02:05

0:00:18

0:00:18

0:02:49

0:02:49

0:19:35

0:19:35

0:02:44

0:02:44

0:02:57

0:02:57

0:13:31

0:13:31

0:10:39

0:10:39

0:20:39

0:20:39

0:16:17

0:16:17

0:18:03

0:18:03

0:04:26

0:04:26

0:51:13

0:51:13

0:13:47

0:13:47

0:21:24

0:21:24

0:16:03

0:16:03

0:00:18

0:00:18