filmov

tv

What are PROPRESS Fittings? | GOT2LEARN

Показать описание

Join my plumbing forum for FREE!

DISCLAIMER: Got2Learn is NOT responsible for any damage done to a property of which the plumbing wasn't done by a professional, I do not recommend doing your own plumbing if you are unsure about what you are doing, always hire a LICENSED contractor when doing any type of plumbing so you can be covered by insurances if something does happen, these videos are for entertainment purposes only!

DISCLAIMER: Got2Learn is NOT responsible for any damage done to a property of which the plumbing wasn't done by a professional, I do not recommend doing your own plumbing if you are unsure about what you are doing, always hire a LICENSED contractor when doing any type of plumbing so you can be covered by insurances if something does happen, these videos are for entertainment purposes only!

What are PROPRESS Fittings? | GOT2LEARN

How to ProPress Copper Pipes (Pros & Cons) | GOT2LEARN

How to Make the PERFECT Press Joint

Do O-Rings Really Leak Over Time? Testing PROPRESS

Copper Plumbing - Viega ProPress vs. Soldered

I Found 2 Month Old Propress Fitting Leaking - Why is it Happening?

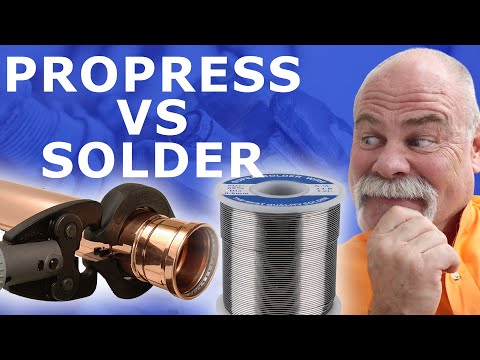

Is ProPress Better Than Solder Plumbing Fittings??

#ProPress #viega #shorts

ProPress vs Push Fittings | Pressure Test

Soldering Copper Pro Press Fittings, REALLY?🤔#plumbing

$110 pro press tool! I’m pressing @ViegaLLC fittings #viega #propress #pressmaster

How to ProPress Copper Fittings (the Good and the Bad)

Remove #ProPress Sharp Edges #shorts

How to Distinguish Viega ProPress Fittings

the best pro press fittings money can buy #Viega #ProPress #Pressmaster #SponsoredPost

Distance between #ProPress fittings #viega #shorts

Testing out iCrimps Handheld ProPress Tool @IWISS #iCrimp #iWiss #iwisstools #plumber #plumbing

Propress fittings

The One and Only Viega ProPress - Copper Press Fittings

IBOSAD Copper Press Tool Review - $100 ProPress! (See update in description)

Can you remove and repress a new ProPress fitting?

ProPress to PEX Transition #shorts

Tutorial on connecting Propress fittings. Using Milwaukee press tool.

#ProPress street fittings #viega #shorts

Комментарии

0:00:57

0:00:57

0:11:02

0:11:02

0:00:32

0:00:32

0:04:21

0:04:21

0:15:32

0:15:32

0:03:08

0:03:08

0:08:57

0:08:57

0:00:33

0:00:33

0:09:23

0:09:23

0:00:39

0:00:39

0:01:01

0:01:01

0:12:05

0:12:05

0:00:17

0:00:17

0:02:06

0:02:06

0:01:01

0:01:01

0:00:08

0:00:08

0:00:47

0:00:47

0:00:20

0:00:20

0:03:48

0:03:48

0:04:30

0:04:30

0:01:54

0:01:54

0:00:24

0:00:24

0:05:19

0:05:19

0:00:38

0:00:38