filmov

tv

Pressure Testing a Gas Line! How to Pressure Test Natural Gas and Propane Lines Correctly!

Показать описание

Pressure Testing a Gas Line! How to Pressure Test Natural Gas and Propane Lines Correctly!

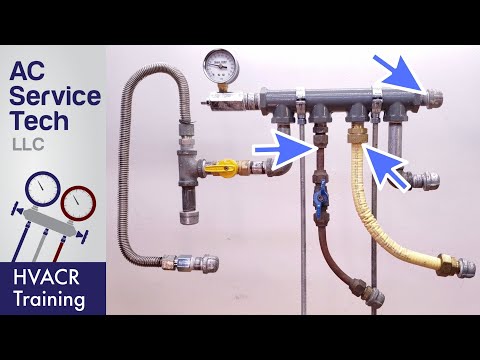

These are some of the reasons I use a 6 PSIG Pressure Test for Testing Low-Pressure Natural Gas and Low-Pressure Propane Gas lines per International Fuel Gas Code IFGC. I go over what gases to use to pressure test, how high to pressure test, and why what maximum pressure the gauge should be as well as other tips! Supervision is needed by a licensed HVAC Tech before doing this as Experience and Apprenticeship garners Wisdom and Safety.

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Our Related Videos/Articles

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Our HVACR Educational Books, E-Books, Workbooks, Cards, Posters, and PowerPoints:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Our HVACR Online Resources!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Tools Used in Our Videos!

Support the Channel by purchasing tools through TruTech Tools!

Save 8% at checkout using code "acservicetech"

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Follow Us On Our Social Media & Podcasting Channels!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

⚠️ Disclaimer:

Information in this video is intended for educational purposes only. Any work related to the topics in this video should be performed by licensed technicians or by apprentices under the supervision of licensed technicians. AC Service Tech LLC is not responsible for any possible damages or injuries caused by the use or misuse of any information provided. ▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

#hvacr #hvacr #hvactrainingvideos #hvactraining #hvactraining101 #acservice #acservicetech #quickrefrence #meteringdevice #superheat #charge #testgauge #superheat #subcooling #temperature

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Shop through Amazon! Your Purchases through Amazon provide a means for channels such as mine to earn advertising fees from all purchases after clicking through. Prices are the same as normal.

These are some of the reasons I use a 6 PSIG Pressure Test for Testing Low-Pressure Natural Gas and Low-Pressure Propane Gas lines per International Fuel Gas Code IFGC. I go over what gases to use to pressure test, how high to pressure test, and why what maximum pressure the gauge should be as well as other tips! Supervision is needed by a licensed HVAC Tech before doing this as Experience and Apprenticeship garners Wisdom and Safety.

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Our Related Videos/Articles

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Our HVACR Educational Books, E-Books, Workbooks, Cards, Posters, and PowerPoints:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Our HVACR Online Resources!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Tools Used in Our Videos!

Support the Channel by purchasing tools through TruTech Tools!

Save 8% at checkout using code "acservicetech"

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Follow Us On Our Social Media & Podcasting Channels!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

⚠️ Disclaimer:

Information in this video is intended for educational purposes only. Any work related to the topics in this video should be performed by licensed technicians or by apprentices under the supervision of licensed technicians. AC Service Tech LLC is not responsible for any possible damages or injuries caused by the use or misuse of any information provided. ▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

#hvacr #hvacr #hvactrainingvideos #hvactraining #hvactraining101 #acservice #acservicetech #quickrefrence #meteringdevice #superheat #charge #testgauge #superheat #subcooling #temperature

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Shop through Amazon! Your Purchases through Amazon provide a means for channels such as mine to earn advertising fees from all purchases after clicking through. Prices are the same as normal.

Комментарии

0:07:31

0:07:31

0:01:11

0:01:11

0:11:17

0:11:17

0:10:57

0:10:57

0:03:59

0:03:59

0:07:53

0:07:53

0:01:01

0:01:01

0:00:33

0:00:33

0:00:19

0:00:19

0:10:11

0:10:11

0:01:54

0:01:54

0:04:27

0:04:27

0:18:21

0:18:21

0:04:09

0:04:09

0:20:21

0:20:21

0:10:23

0:10:23

0:08:00

0:08:00

0:01:29

0:01:29

0:01:00

0:01:00

0:00:15

0:00:15

0:00:17

0:00:17

0:00:45

0:00:45

0:00:22

0:00:22

0:01:01

0:01:01