filmov

tv

Fine Engine Tuning With A Vacuum Gauge

Показать описание

Here's everything you need to know about using a vacuum gauge as a tuning device. A few great ways to dial things in, and one that definitely sucks.

Fine Engine Tuning With A Vacuum Gauge

8.12-Edelbrock AVS2 Fine Tuning

Initial Carburetor Performance Tuning

Holley Carb Tuning Tips! | Engine Masters | MotorTrend

Fine Carburetor Tuning Using Fish Tank Accessories - Regulated Vacuum Leak For A Cleaner Idle

Tuning Your Classic Car

Fine Tuning with T Slots and Bleeds

IGNITION TIMING SIMPLIFIED | The secrets of spark tuning revealed

CARX STREET Mobile: Paul Walker's Mitsubishi Eclipse Customization & Tuning Guide |1's...

Do You Know THE CARB TUNING SECRET? How YOU Can TUNE Like A MASTER Nitro Engine Tuner

The Ultimate Edelbrock Carburetor Tuning Guide

Fine Tuning Holley Carburetors For Dual Quad Intakes

Fine-tuning the carburetors on a Krash 997 engine by JS Powersports

CARB TUNING 101: Tuning basics explained!

Fine tuning Engine 1 by tommy @ Chief custom engine

Tuning my F100 with Vacuum Gauge

3 Different Methods for Tuning a Car [4k]

Rochester Carburetor tuning.

⚠️Fine tuning an engine bay⚠️

Tuning Holley Sniper

The Ultimate Holley 4150 Tuning Video! ( As easy as 1 2 3 sort of )

Sniper EFI Idle Tuning

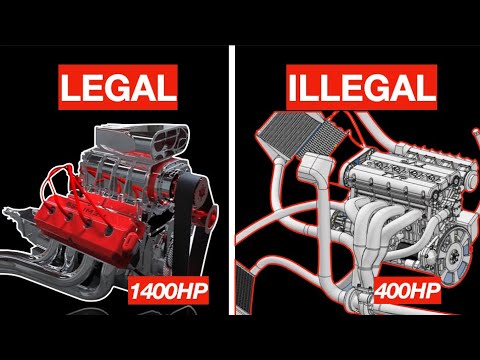

How Tuning Engines Became Illegal👮🏻♂️| Explained Ep.26

Stock engine, stock carburatore, only fine tuning 4Af engine

Комментарии

0:11:08

0:11:08

0:15:20

0:15:20

0:12:19

0:12:19

0:03:24

0:03:24

0:11:25

0:11:25

0:17:21

0:17:21

0:07:14

0:07:14

0:05:24

0:05:24

0:29:32

0:29:32

1:21:16

1:21:16

0:16:44

0:16:44

0:18:07

0:18:07

0:01:15

0:01:15

0:21:11

0:21:11

0:01:39

0:01:39

0:14:19

0:14:19

0:05:46

0:05:46

0:01:46

0:01:46

0:04:11

0:04:11

0:01:13

0:01:13

0:45:23

0:45:23

0:05:48

0:05:48

0:13:04

0:13:04

0:00:17

0:00:17