filmov

tv

Best Custom CPU Heat Spreaders by BartX - Lapping or Custom IHS VS Direct Die?

Показать описание

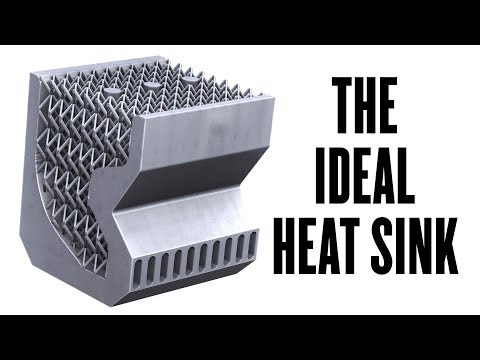

This week I got 2 brand new custom heat spreaders from BartXStore. A large nickel coated one for the 28 Core Xeon W-3175X and the final version of the full copper IHS for Kaby Lake-X like 7740X. On the video I go through my own opinions about different IHS solutions on Intel CPUs, as I often see videos and conversations about CPU lapping, custom heat spreaders and Direct Die cooling.

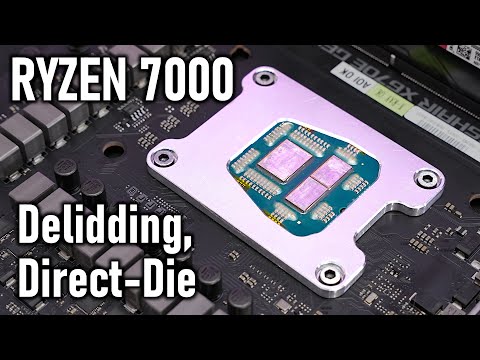

My own opinion is that people should not lap a CPU which they only use in their daily PC, if the CPU can be delidded. Lapping is a lot more certain way to lose the warranty of your CPU, compared to just delidding for example. If your CPU can be delidded, you can get a lot better performance by using direct die solution than lapping the stock Intel IHS for a few degrees. Lapping has its risks if done wrong, the actual cooling performance can become much worse, and in the worst case scenario the IHS can be rendered useless if it is lapped too much and the cooler will not make adequate contact anymore.

With CPUs that can be delidded, but direct die is not an option, like Skylake/Kaby Lake mainstream CPUs where the PCB thickness is too thin to make adequate contact with the die itself, then a custom IHS is a better option than lapping the stock Intel IHS. You can get a really good custom IHS for relatively low cost, save all the effort of lapping the IHS manually and often get even better cooling performance.

When a CPU can not be delidded effectively and safely, and when it is not something that is wise to do, such as Skylake-X Refresh and Cascade Lake-X CPUs, aswell as mainstream Coffee/Comet Lake 9900K/10900K CPUs, then a lapping can be a method to increase your cooling performance. When the soldered TIM is the desired thermal interface material between the die and the IHS, as it is the best performing one under subzero cooling, the only way is to use the stock Intel IHS, and only lapping can make the contact surface better as it can't be replaced.

My own opinion is that people should not lap a CPU which they only use in their daily PC, if the CPU can be delidded. Lapping is a lot more certain way to lose the warranty of your CPU, compared to just delidding for example. If your CPU can be delidded, you can get a lot better performance by using direct die solution than lapping the stock Intel IHS for a few degrees. Lapping has its risks if done wrong, the actual cooling performance can become much worse, and in the worst case scenario the IHS can be rendered useless if it is lapped too much and the cooler will not make adequate contact anymore.

With CPUs that can be delidded, but direct die is not an option, like Skylake/Kaby Lake mainstream CPUs where the PCB thickness is too thin to make adequate contact with the die itself, then a custom IHS is a better option than lapping the stock Intel IHS. You can get a really good custom IHS for relatively low cost, save all the effort of lapping the IHS manually and often get even better cooling performance.

When a CPU can not be delidded effectively and safely, and when it is not something that is wise to do, such as Skylake-X Refresh and Cascade Lake-X CPUs, aswell as mainstream Coffee/Comet Lake 9900K/10900K CPUs, then a lapping can be a method to increase your cooling performance. When the soldered TIM is the desired thermal interface material between the die and the IHS, as it is the best performing one under subzero cooling, the only way is to use the stock Intel IHS, and only lapping can make the contact surface better as it can't be replaced.

Комментарии

0:21:57

0:21:57

0:19:29

0:19:29

0:10:32

0:10:32

0:18:51

0:18:51

0:14:22

0:14:22

0:29:49

0:29:49

0:00:20

0:00:20

0:17:21

0:17:21

1:10:58

1:10:58

0:08:29

0:08:29

0:21:02

0:21:02

0:00:14

0:00:14

0:37:16

0:37:16

0:07:13

0:07:13

0:11:04

0:11:04

0:05:46

0:05:46

0:28:31

0:28:31

0:22:39

0:22:39

0:24:19

0:24:19

0:21:50

0:21:50

0:08:41

0:08:41

0:02:45

0:02:45

0:05:53

0:05:53

0:14:54

0:14:54