filmov

tv

Explaining the depth stop i made for my dovetail saw

Показать описание

I just built a dovetailed speaker stack and some people noticed my saw and asked about it, hope this helps

thank you for watching My videos are for entertainment only. Woodworking can be dangerous. The methods I use are my methods, and are not necessarily correct or safe! If in doubt, DON'T DO IT, it is best to learn more before you start. And always remember to read, understand and follow, all the manufacturers instructions that come with your tools. Always wear all necessary protection equipment, the safety in your workshop is your responsibility,

Be safe and have fun,happy making

thank you for watching My videos are for entertainment only. Woodworking can be dangerous. The methods I use are my methods, and are not necessarily correct or safe! If in doubt, DON'T DO IT, it is best to learn more before you start. And always remember to read, understand and follow, all the manufacturers instructions that come with your tools. Always wear all necessary protection equipment, the safety in your workshop is your responsibility,

Be safe and have fun,happy making

Explaining the depth stop i made for my dovetail saw

How to Use the Depth Stop for Precise Woodworking Cuts

Exact Router Depth with Turret Depth Stops | Tricks of the Trade

THE BEST Drill Press Depth Stop And Key Holder

FastFix Adjustable Countersink Depth Stop / Depth Control Chuck Attachment

Homemade Drill Press Depth Stop / Depth Gauge

Drill Press Depth Stop

Depth stop for the Festool Domino for shallower mortises #woodwork #woodworkingtools #festool

111: Minimum Depth of Binary Tree | JavaScript Solution Explained | LeetCode 101

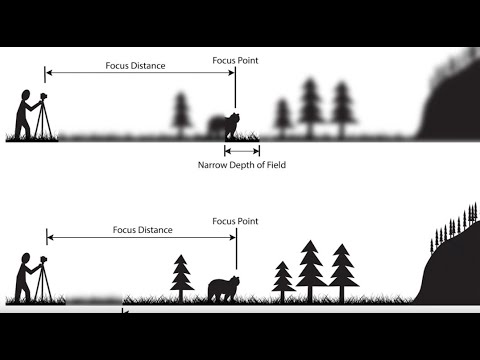

Depth of Field: An Easy Overview (2023)

You are Analyzing Market WRONG! Market Depth Analysis in Trading for Beginners | Trading Strategy

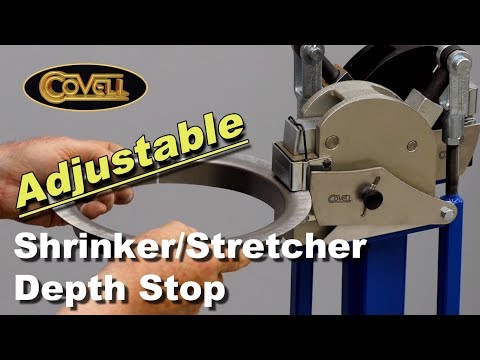

Covell Adjustable Shrinker/Stretcher Depth Stop

Milling machine quick adjust depth stop

This Will Transform Your Ball Striking! Depth Explained!

One way to set drill depth.

How to use the ROUTER depth stop #woodworking #router #woodworkingtool

Understanding Depth of Field: How Aperture Affects DOF

A Simple Guide to Depth of Field

Instant Drill Press Depth Stop

Internal Spindle Stop for the Mini Lathe - Making a Lathe Depth Stop

How to operate a Shaper / Shaper Depth Stop Pt.1

How to PROPERLY use a plunge router's depth gauge

Depth Gouge For Depth Stop On A Drillbit

Audio Basics - Understanding Bit Depth

Комментарии

0:01:30

0:01:30

0:00:42

0:00:42

0:03:32

0:03:32

0:06:45

0:06:45

0:00:58

0:00:58

0:10:57

0:10:57

0:15:53

0:15:53

0:00:52

0:00:52

0:08:18

0:08:18

0:03:47

0:03:47

0:14:40

0:14:40

0:05:48

0:05:48

0:20:24

0:20:24

0:09:51

0:09:51

0:00:26

0:00:26

0:00:59

0:00:59

0:01:07

0:01:07

0:16:29

0:16:29

0:11:23

0:11:23

0:25:42

0:25:42

0:12:07

0:12:07

0:05:35

0:05:35

0:25:09

0:25:09

0:06:04

0:06:04