filmov

tv

How to tap steel | tapping steel | ultimatehandyman

Показать описание

How to tap steel | tapping steel | ultimatehandyman

Everything you need to know about drilling and tapping holes | DIY

How to tap threads using a drill

How to Use a Tap and Die Set

How to drill and tap a hole (In 3 mins)

DIY Threads Hand Tapping | how to tap metal | Tapping Steel #Shorts

Learn to use a Tap & Die to Cut Threads

These Screws CAN DRILL STRAIGHT INTO METAL! (Self-Drilling Screws...Fasten Anything To Metal!)

Adam Savage's One Day Builds: Thread Tapping Guide Block!

Stainless Steel - threading tip

How to make a Thread Tap - How to easily tap a thread - DIY Thread Tap - Putting a tread into metal.

Everything You Need to Know About Taps & Dies - Gear Up With Gregg's

STOP Buying Standard Taps...Buy This Instead

How to Power Tap

Repairing Stripped Nuts and Bolts: How To Use Tap and Die Sets | Eastwood

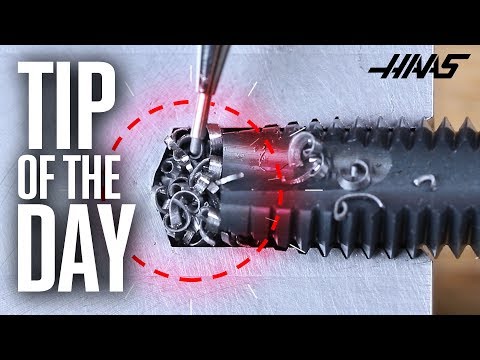

Tapping Essentials - Every Machinist Needs to Watch This - Haas Automation Tip of the Day

Drill Tap Bits 3/8 Steel #shorts

the CHALLENGES tapping threads into stainless steel

Broken bolt extractor

Countersink a screw in stainless steel - drill, countersink, machine tap

how and why to use a “TAPERED” tap (NPT thread) National Pipe Thread

Make a Hand Tap with a steel screws

👌👍How to clean steel taps with 👍Colgate 🚿🛁🪥

Drilling tap hole for STAINLESS STEEL kitchen sinks

Комментарии

0:07:34

0:07:34

0:22:12

0:22:12

0:03:22

0:03:22

0:09:03

0:09:03

0:02:57

0:02:57

0:00:18

0:00:18

0:05:27

0:05:27

0:05:23

0:05:23

0:41:23

0:41:23

0:00:23

0:00:23

0:01:33

0:01:33

0:08:46

0:08:46

0:07:53

0:07:53

0:11:22

0:11:22

0:07:36

0:07:36

0:13:20

0:13:20

0:00:27

0:00:27

0:05:38

0:05:38

0:00:20

0:00:20

0:01:57

0:01:57

0:03:16

0:03:16

0:03:51

0:03:51

0:00:39

0:00:39

0:00:44

0:00:44