filmov

tv

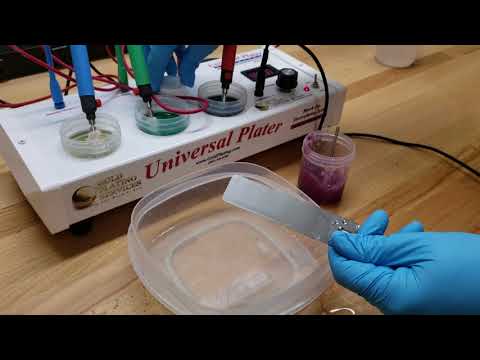

Nickel Plating - Step by step guide

Показать описание

Welcome to my new channel! With this video, I hope to show you how you can electroplate at home for pennies. Well, maybe more than a few pennies but its super easy. This channel will ultimately be about watch restorations—complete restorations from scratch. I am brand new to horology so this will be a trip you can take with me.

The following are affiliate links. They help me out a ton and do not cost you a single penny more when used:

The following are affiliate links. They help me out a ton and do not cost you a single penny more when used:

Nickel Plating - Step by step guide

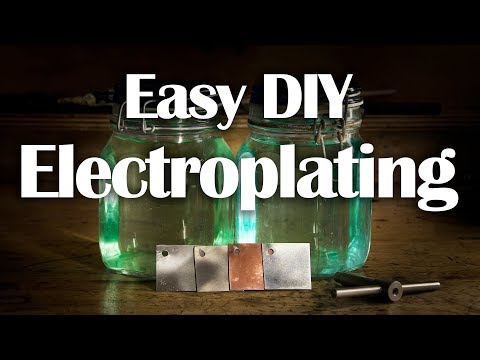

Electroplating - Easy DIY Nickel, Copper, Zinc Plating

Copper-nickel electroplating process for aluminum alloy workpiece

Nickel Electroplating in the Home Shop - A Shocking Way to Prevent Rust!

Ni-305 Bright Nickel Electroplating Process for Automobile Parts

ELECTROLESS NICKEL Plating Tutorial

Can you electroless nickel plating

Acid copper plating technology

nickel plating process steps

How to Nickel Electroplate at Home | bit-tech Modding

Zinc-Nickel Plating: Why Use it and How to Apply it?

Easy DIY nickel plating with home found stuff

DIY Nickel Plating (Sa gusto matuto add me on my FB)

How to nickel plate at home - a detailed DIY guide to simple electroplating restoration.

Electroless nickel plating on brass

DIY Nickel Electroplating Solution

nickel plating process steps Lohe ki jindgi bana dege

How to make the Nickel Plating Solution / Amazing Workshop

Take you to understand the hard chrome plating process#electroplating #chrome #chromeplating

Metal Plating Process | A Complete Guide To Its Types And Technique.

Making the switch to Single Component Electroless Nickel. One Plate is simple and convenient!

How to Nickel Plate & Gold Plate onto Steel (Guns etc.)

DIY Nickel Plating

No electrolytic nickel plating, nickel plating without conducting electricity, very simple

Комментарии

0:18:42

0:18:42

0:09:38

0:09:38

0:00:35

0:00:35

0:14:23

0:14:23

0:00:15

0:00:15

0:05:58

0:05:58

0:00:13

0:00:13

0:00:12

0:00:12

0:00:16

0:00:16

0:28:22

0:28:22

0:08:46

0:08:46

0:01:00

0:01:00

0:00:16

0:00:16

0:24:48

0:24:48

0:00:32

0:00:32

0:01:00

0:01:00

0:00:16

0:00:16

0:04:43

0:04:43

0:00:09

0:00:09

0:07:39

0:07:39

0:01:24

0:01:24

0:08:30

0:08:30

0:00:11

0:00:11

0:00:22

0:00:22