filmov

tv

a better way to layout your workshop

Показать описание

Get _The Brief Guide To Joinery_ *FREE E-BOOK* here:

DO YOU LIKE MY WORKBENCH? I have build PLANS here:

FULL ARTICLE:

BUILD PLANS FOR SALE:

US & CANADIAN AFFILIATE LINKS

DOWELMAX:

DOWELMAX 3/8" Kit:

DOWELMAX 1/2" Expansion:

BLADES:

TOOLS:

BITS:

SUPPLIES

INSTAGRAM:

MUSIC:

Epidemic Sound

Use my referral link and start your free 30-day trial:

DO YOU LIKE MY WORKBENCH? I have build PLANS here:

FULL ARTICLE:

BUILD PLANS FOR SALE:

US & CANADIAN AFFILIATE LINKS

DOWELMAX:

DOWELMAX 3/8" Kit:

DOWELMAX 1/2" Expansion:

BLADES:

TOOLS:

BITS:

SUPPLIES

INSTAGRAM:

MUSIC:

Epidemic Sound

Use my referral link and start your free 30-day trial:

a better way to layout your workshop

A Better Way To Layout Your Stones: ArrayCrvPLUS

6 Tips For a Better Shop Layout #shoptour

How To Design Good Layouts

How can we design a better way to learn?: Meghan Athavale at TEDxWinnipeg

32 PRO TIPS To Make BILLIONS In Grow A Garden!

How to ACTUALLY Get Better at Graphic Design (My Playbook)

Your shop needs a better layout (Tip 2) #woodworking #woodshop

How Can We Design Better Streets?

Why doesn't the green man flash anymore?

How to Build a GOOD Bloxburg House SHAPE and LAYOUT

How To Make A Good Layout! (Geometry Dash 2.11) [FULL GUIDE FOR BEGINNERS] | DeVeReL

Design Better Than 99% of UI Designers

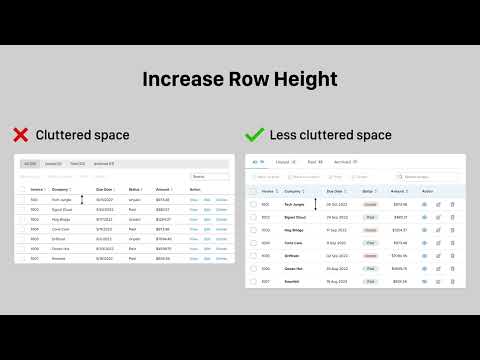

UI Design Tips for a Better Data Table UX

How to change your iphone keyboard layout #shorts

How to plant potatoes and get a lot of big tubers

The SECRET Setting To Edit FASTER on Fortnite! (Console & PC!) #shorts

Many ways to furnish a 3mx3m room! #smallspace #fengshui #bedroom #dorm #smallapartment #tinyhouse

10 TIPS To BECOME RICH in GROW A GARDEN! ROBLOX

How To GET ALL SEEDS FOR FREE in GROW A GARDEN! ROBLOX

A Day in the Life of an Architecture Major

HOW TO GET BEANSTALK SEED (FREE) SHOWCASE in GROW A GARDEN! ROBLOX GROW A GARDEN

Altium Design 21: A Better Way to Design - What's New Webinar

Another Way To Layout Stair Stringers With Only A Level, Pencil And Tape Measure

Комментарии

0:15:44

0:15:44

0:15:04

0:15:04

0:10:09

0:10:09

0:07:33

0:07:33

0:04:44

0:04:44

0:07:10

0:07:10

0:09:41

0:09:41

0:00:20

0:00:20

0:00:19

0:00:19

0:16:50

0:16:50

0:17:22

0:17:22

0:16:12

0:16:12

0:14:52

0:14:52

0:04:28

0:04:28

0:00:11

0:00:11

0:00:34

0:00:34

0:00:21

0:00:21

0:00:29

0:00:29

0:12:20

0:12:20

0:08:07

0:08:07

0:00:29

0:00:29

0:03:07

0:03:07

0:59:55

0:59:55

0:10:04

0:10:04