filmov

tv

Making a Hot Wire Cutter for Shaping Foam

Показать описание

In this video I'm building myself a hot wire cutter so I can cut larger and more intricate shapes into the foam I use in my projects.

Want to support the channel? Check out the Patreon:

Or grab yourself something from the shop:

IG: @chrisfromgoodroads

Tunes by Drew McCann:

Want to support the channel? Check out the Patreon:

Or grab yourself something from the shop:

IG: @chrisfromgoodroads

Tunes by Drew McCann:

Making a Hot Wire Cutter for Shaping Foam

Homemade Styrofoam hot wire cutter

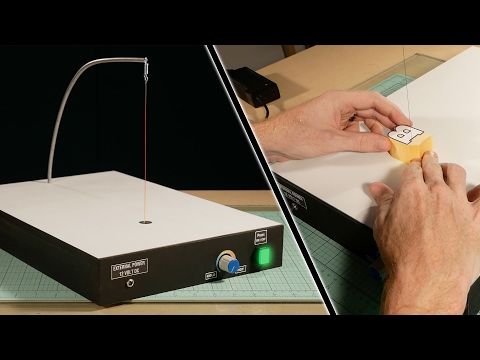

Build Your Own Hot Wire Foam Cutter - Professional Tools for Modelers

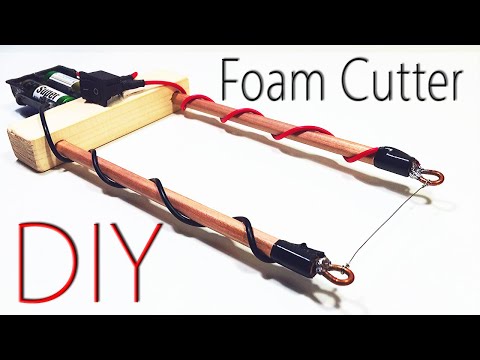

How to make hot wire foam cutter , Amazing tool 2019

Build Your Own Hot Wire Foam Cutter-Ultimate DIY Slicer Test

DIY Hot Wire Foam Cutter, What It Does, and How To Cut an Airfoil

How To Make A Hot Wire Cutter From An Old PC

How to make a Foam Cutter at Home? Awesome DIY project! Wow!

Make A Hot Wire Foam Cutter || DIYFoam Cutting Machine 🤖 #diy

DIY - Hobby crafts HOT WIRE CUTTER for under £3

Making models with a hot-wire cutter

Building a hot-wire foam cutter

Tips & Tutorial for Foam Hot Wire Cutters & knives

Adam Savage's Favorite Tools: Hot Wire Cutter!

How To Make Handheld Hot Wire Foam Cutter ( Simple )

How to Make a Hot Wire Foam Cutter for Styrofoam

DIY. Hot Wire Foam Cutter ( Large Format )

The Hot Wire Foam Cutter & DIY Foam Cutting Machine

Make A Hot Wire Foam Cutter DIY Foam Cutting Machine

Making a Hot Wire Foam Cutter | DIY Foam Cutting Machine

Design of a Bow Hot-Wire Cutter

Homemade Styrofoam hot wire cutter

ADJUSTABLE hot wire Foam Cutter - by VOGMAN

AMAZING!! polystyrene Cutting Machine DIY

Комментарии

0:07:30

0:07:30

0:05:32

0:05:32

0:11:21

0:11:21

0:10:57

0:10:57

0:01:32

0:01:32

0:26:38

0:26:38

0:12:32

0:12:32

0:04:45

0:04:45

0:01:01

0:01:01

0:08:59

0:08:59

0:45:32

0:45:32

0:16:34

0:16:34

0:13:05

0:13:05

0:12:26

0:12:26

0:04:20

0:04:20

0:15:28

0:15:28

0:06:36

0:06:36

0:04:34

0:04:34

0:13:05

0:13:05

0:10:46

0:10:46

0:14:03

0:14:03

0:09:44

0:09:44

0:20:09

0:20:09

0:21:48

0:21:48