filmov

tv

Effect of residual flux on a strain gage.

Показать описание

Can you find what’s wrong with the high-temperature sensor in this video?

Let’s examine – How to deal with a “Resistance” to change? 🤔

As the old saying goes: “Flux is your friend while you’re soldering and then basically is your enemy once you’re done!” 💔

👉 Always ensure no flux gets on the grid of a strain gage, as the resistance shift will be accelerated.

Let’s examine – How to deal with a “Resistance” to change? 🤔

As the old saying goes: “Flux is your friend while you’re soldering and then basically is your enemy once you’re done!” 💔

👉 Always ensure no flux gets on the grid of a strain gage, as the resistance shift will be accelerated.

Effect of residual flux on a strain gage.

Effect of residual flux on a strain gauge (Gage Installation Tester)

L37: Effect of Residual Flux on Switching Transients | Doubling Effect | Transformers | In Hindi

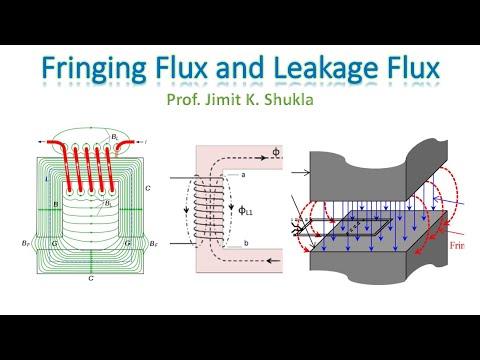

Fringing Flux and Leakage Flux and their effects

Magnetic Energy of Hysteresis

Magnetic flux explained in 3 minutes

Amazing Discovery With Magnets - The Inverter Magnet

Coercivity & retentivity (Permanent & electromagnets) | Magnetism & matter | Physics | K...

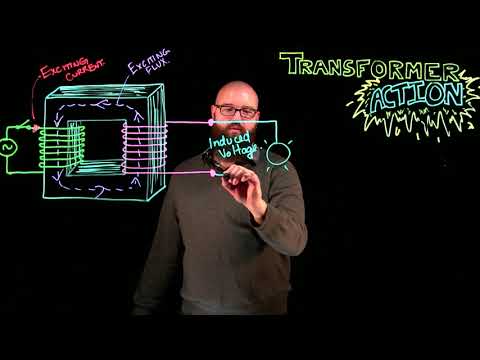

Transformer Action

Magnetic Flux and Magnetic Flux Density

Electronics: Residual flux conductivity on PCBs causing problems?

Current Transformers (CT)

How Induction Heating works ?

[CFD] Residuals in CFD (Part 4) - Global Imbalance

Become An Electrical Lineworker

Working Principle of DC Motor (animation of elementary model)

Magnetic Particle Inspection

Residual Field Magnetic Flux Leakage Wire Rope Inspection

Magnetic Flux Density — Lesson 3

Solenoid Basics Explained - Working Principle

Distortion in Welding

What Is Flux? | Soldering

Inductors Explained - The basics how inductors work working principle

Clean your flux after soldering

Комментарии

0:03:57

0:03:57

0:06:44

0:06:44

0:11:48

0:11:48

0:05:34

0:05:34

0:07:36

0:07:36

0:03:23

0:03:23

0:02:41

0:02:41

0:08:53

0:08:53

0:06:38

0:06:38

0:04:36

0:04:36

0:01:18

0:01:18

0:14:31

0:14:31

0:02:31

0:02:31

![[CFD] Residuals in](https://i.ytimg.com/vi/3xfaM0IcRXE/hqdefault.jpg) 0:38:18

0:38:18

0:00:24

0:00:24

0:05:36

0:05:36

0:03:53

0:03:53

0:00:23

0:00:23

0:01:17

0:01:17

0:09:09

0:09:09

0:11:37

0:11:37

0:02:45

0:02:45

0:10:20

0:10:20

0:00:26

0:00:26