filmov

tv

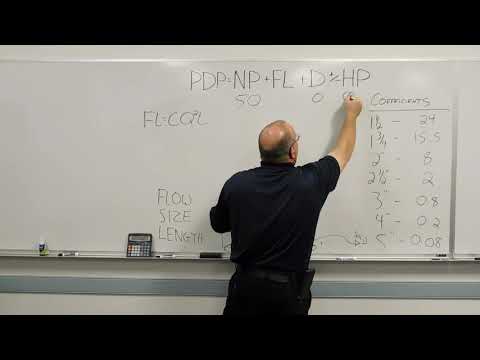

Hand Method for Calculating Friction Loss for Firefighters

Показать описание

Hand Method for Calculating Friction Loss for Firefighters

The 'Q' Method

Calculating Friction Loss

Calculating friction loss in a relay with 4 inch hose

Using the coefficient method to calculate friction loss in attack lines

How to calculate and overcome friction loss

Calculating friction loss in a relay with 3 inch hose

How to Slay Friction Loss #firefighter #watersupply #hydrant

Friction Loss demo.

Pump Operations Lesson #5 Friction Loss 1 3/4 Inch Hose

Pump Operations Lesson #4 Friction Loss 2 1/2 inch Hose

Angular Momentum Bike Wheel Demo - Short version

F1 Cars Have No Keys 🤯

Simple Machines - Pulley based

Using Magnets to Move Toy Car 😲 🔥

Friction loss for 2 1/2 inch and 1 3/4 inch hose

How to Wheelie your bike in a nutshell⚡️ #mtb #short #shortsvideo

Calculating friction loss in a relay with 5 inch hose

Maths working model, addition, subtraction, multiplication, division

Master Back Meridian Massage Techniques #backmassage #backpainrelief #bodycare #backpain

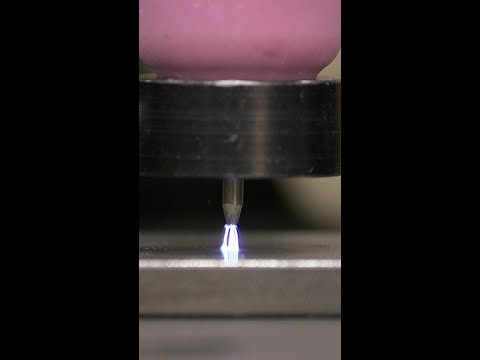

Beginner TIG welders NEED to know this...

Addition Trick |🦋Butterfly Method for addition fraction |Fraction Trick #shorts #fraction #tricks

A very professional Masonry work specifically when you have to place the last brick@GIMS

Fraction wheel |kids math activities | fraction activity for kids #earlylearning #kidsactivities

Комментарии

0:08:23

0:08:23

0:03:51

0:03:51

0:05:15

0:05:15

0:07:38

0:07:38

0:10:25

0:10:25

0:02:01

0:02:01

0:08:11

0:08:11

0:00:57

0:00:57

0:03:44

0:03:44

0:08:07

0:08:07

0:09:25

0:09:25

0:00:50

0:00:50

0:00:21

0:00:21

0:00:08

0:00:08

0:00:14

0:00:14

0:13:36

0:13:36

0:00:15

0:00:15

0:11:51

0:11:51

0:00:16

0:00:16

0:00:20

0:00:20

0:00:18

0:00:18

0:00:23

0:00:23

0:00:13

0:00:13

0:00:39

0:00:39