filmov

tv

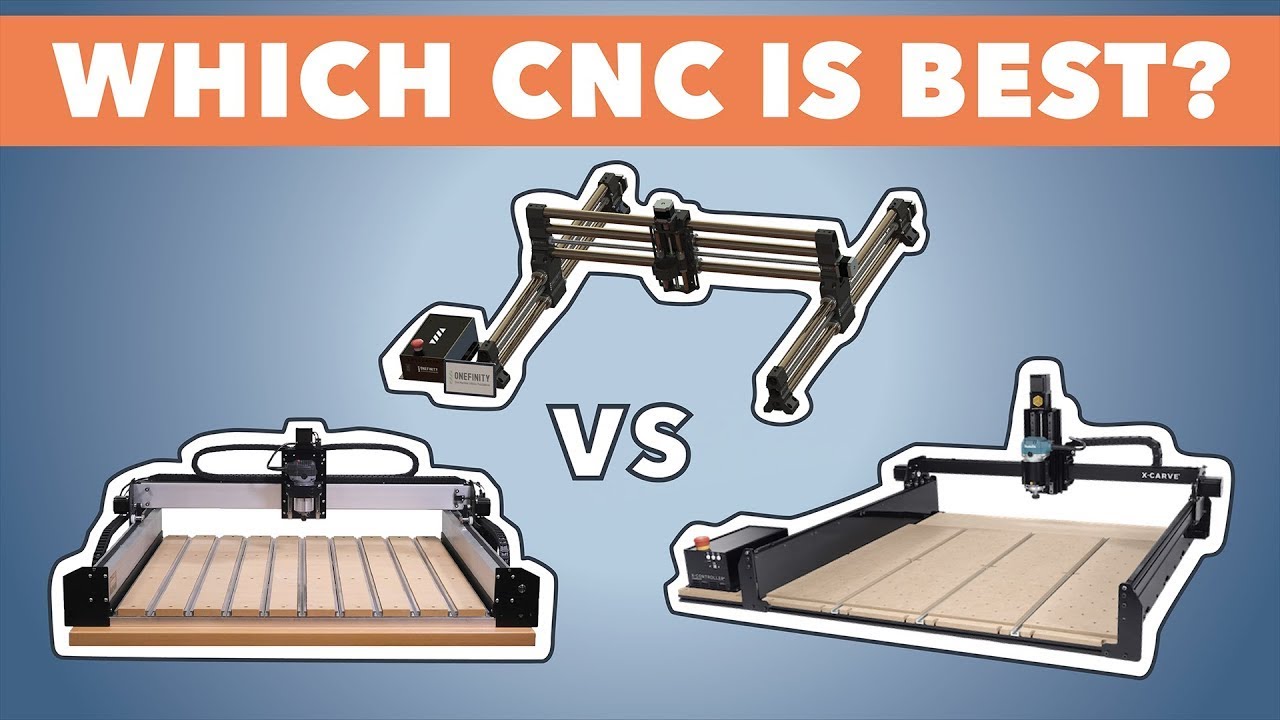

The Ultimate Desktop CNC Router Comparison - Which Should You Buy?

Показать описание

THIS VIDEO IS NOT SPONSORED IN ANY WAY

Timestamps

X-Carve - 1:01

Shapeoko - 9:11

Onefinity - 17:15

Tools To Help You Make Money With Your CNC

Interested in getting started in CNC, but don't know where to start?

A great way to support Andy Bird Builds is to purchase through affiliate links, you get what you need and I may get a kickback!

#andybirdbuilds #cncrouter #cnccomparison

The Ultimate Desktop CNC Router Comparison - Which Should You Buy?

Watch BEFORE You Buy a CNC Router in 2024

Best CNC Router Machine for Beginners in 2024 | Top 5 | Cut/Engraving

Top 5 BEST CNC Router Machine in [2024]

Meet EVO | The best desktop CNC for hobbyists & small businesses

What Can a $150 CNC Do?! Vevor 3018 Pro CNC Router Review

Best CNC for Garage Shops! Shapeoko 5 Pro! #woodworkingtools

Is the Shapeoko HDM the worlds best desktop cnc in 2022?

The Ultimate CNC Router Review Buyers Guide, Best CNC Routers

Best CNC Router Machines 2024 - (For Beginners & Pros!)

Carvera - The Perfect Desktop CNC Mill?

The Hobby CNC That You'll Never Outgrow

Watch This BEFORE Buying a CNC Machine (10 regrets to avoid)

Watch This Before You Buy A Desktop CNC Router

5AXISMAKER TT120® - The Ultimate Desktop CNC Machine that Transforms Your Desk into a Factory

The Best Desktop 5-axis CNC Machine | Meet Xmachine XM-100

Best CNC Routers For Beginners 2024 - Only 6 Options You Should Consider

Top 5 Best CNC Routers of 2025 | Precision Cutting Tools – Reviews Inside!

$300 DESKTOP CNC!! Is It Worth It? SainSmart Genmitsu 3018 PROVer V2 #desktopcnc #makemoney

Ultimate Desktop CNC Machine -- TT120

Watch This Before You Buy A CNC Router In 2023

The BEST 4 Axis Desktop CNC Machine?

The Hidden Costs of CNC's!

Affordable Desktop CNC Mill

Комментарии

0:31:02

0:31:02

0:08:55

0:08:55

0:15:28

0:15:28

0:09:35

0:09:35

0:02:20

0:02:20

0:11:49

0:11:49

0:00:33

0:00:33

0:00:15

0:00:15

1:47:57

1:47:57

0:05:06

0:05:06

0:18:27

0:18:27

0:34:48

0:34:48

0:21:21

0:21:21

0:08:49

0:08:49

0:00:34

0:00:34

0:02:43

0:02:43

0:08:23

0:08:23

0:06:34

0:06:34

0:13:46

0:13:46

0:01:03

0:01:03

0:16:34

0:16:34

0:22:07

0:22:07

0:11:48

0:11:48

0:00:44

0:00:44