filmov

tv

Can 3D Printing Finally Compete with Injection Molding?

Показать описание

#form4 #injectionmolding #3dprinting #formlabs #msla3dprinting #stereolithography

Witness the lightning-fast capabilities of Form 4 as it outpaces traditional injection molding methods in speed and quality. Explore how 3D printing is revolutionizing manufacturing, rendering injection molding obsolete. Dive into this Fast and Furious clash of technologies!

▬ Learn More ▬▬▬▬▬▬▬▬▬▬▬▬▬▬

▬ Socials ▬▬▬▬▬▬▬▬▬▬▬▬

👇🏼 Subscribe for more 3D printing videos:

▬ About Formlabs ▬▬▬▬▬▬▬▬▬▬▬▬

Can 3D Printing Finally Compete with Injection Molding?

Is 3D printing FINALLY easy enough to print Warhammer at home? Uniformation GKTwo!

Can your FDM 3D Prints Compete with a Resin?

Bambu Lab X1C Review: FINALLY a 3D Printer for Everyone!

3D Printed Pen vs Real

8 Coolest 3D Prints I Own

3D Printer Reliability: Prusa vs. Bambulab

3D Printing a TURBINE to Produce Cheap Electricity

I Tried Starting A 3D Printing Business In 7 Days

The Evolution of 3D Printing | ConTECHtual | NowThis

I've FINALLY bought a 3D printer - Did I get a good one? SEND HELP!

Review of the Epax X1-4k resin 3d printer. Finally, some competition for the Sonic Mini 4k!

How to get better detail on your #fdm #3dprints. #3dprinting #3dprint

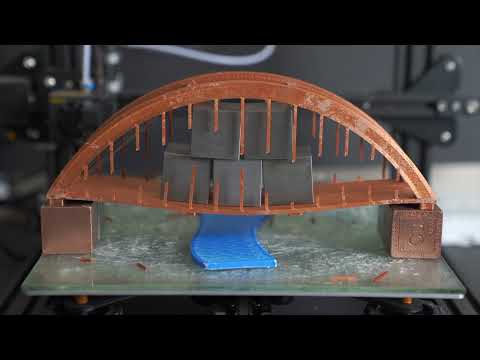

Bridges. Why they don't fall down.

This Record-Breaking 3D Printer Could Be the Future of Manufacturing

12 3D Printing Innovations at FORMNEXT 2024

First impressions of a very competitive 3D printer

3D print tip! FDM vs. SLA #shorts

The 5 Filament Types You Need to Know (And What They're Good For)

HIGH SPEED: 70,400 Nozzles 3D Printing Simultaneously

1508 3D Printing - A History And A Competition

This Will Change 3d Printing Forever!

Next gen 3D printers are here, but do they bring fresh problems?

34+ Exciting 3D Printing Products Announced at FormNext

Комментарии

0:01:26

0:01:26

0:24:08

0:24:08

0:09:19

0:09:19

0:10:32

0:10:32

0:00:40

0:00:40

0:00:50

0:00:50

0:13:15

0:13:15

0:15:39

0:15:39

0:14:58

0:14:58

0:03:13

0:03:13

0:08:28

0:08:28

0:16:05

0:16:05

0:00:44

0:00:44

0:04:44

0:04:44

0:03:47

0:03:47

0:22:09

0:22:09

0:21:17

0:21:17

0:00:20

0:00:20

0:17:28

0:17:28

0:15:05

0:15:05

0:08:05

0:08:05

0:15:49

0:15:49

0:16:23

0:16:23

0:22:30

0:22:30