filmov

tv

Amazon Plastic Welder Review

Показать описание

Amazon Plastic Welder Review

Best Plastic Welder? Weld Repair Stronger Than New? Let’s find out!

AMAZONS BEST PLASTIC WELDER

REVIEWING AMAZON PLASTIC WELDER (THE ALLTURN)

✅ Top 5: Best Plastic Welders On Amazon 2023

Amazon plastic welder let’s see if it works @ironblackbirdcycles

PLASTIC WELDER?! ALLTURN AMAZON

Reviewing the Best Plastic Welders 2024 [ for Easiest Weld Repairs ]

Allturn Upgraded Version 110V-100W Plstic Welder

150W Plastic Welder,2 in 1 Plastic Welding Kit Plastic Repair Welder Soldering Hot Stapler

✅ Best Plastic Welders in 2022-2023 | Top 6 Best Handheld Plastic Welder Reviews

Amazon plastic welder, hot staples!

WRDLOSY Plastic Welder 100W, One Second Heat Up, Plastic Welding Kit Review, Good value and easy to

✅ Top 4: Best Plastic Welders On Amazon 2023 || Top Rated Plastic Welders Review

Will it Melt & Weld? - Allturn Plastic Welder Review!

Plastic Welder/Stapler worth it? (Amazon purchased plastic welder kit review)

Achieving Good Plastic Welding. Repost from @AutoPro1112 #yeswelder #shorts #welding #weld #plastic

Mini $69 Welder Review Cheapest On Amazon

Plastic Welding Gun, From Amazon, First Time Using it, Worth The Money ??

Top 5 best Plastic Welders 2023 🔥

Bondic Liquid Plastic Welder Review!

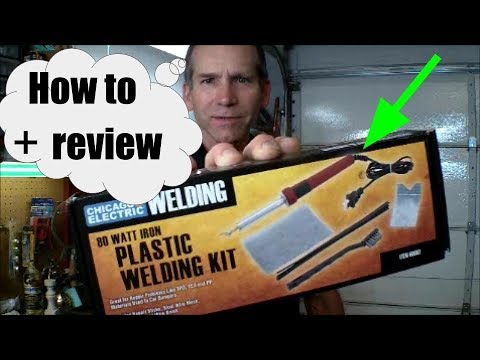

How to use a Harbor Freight Plastic Iron Item 60662

Cordless Plastic Welder Gun for Dewalt 20v Battery, Portable Welding Machine Review

TryE Plastic Welder Heat Gun for HDPE, PE, Vinyl, ABS - Unboxing and Overview Review -

Комментарии

0:07:34

0:07:34

0:14:46

0:14:46

0:04:24

0:04:24

0:10:35

0:10:35

0:05:05

0:05:05

0:00:33

0:00:33

0:07:14

0:07:14

0:11:27

0:11:27

0:07:13

0:07:13

0:09:30

0:09:30

0:06:36

0:06:36

0:00:38

0:00:38

0:02:42

0:02:42

0:08:32

0:08:32

0:12:26

0:12:26

0:08:40

0:08:40

0:00:30

0:00:30

0:05:39

0:05:39

0:13:32

0:13:32

0:05:42

0:05:42

0:07:32

0:07:32

0:11:04

0:11:04

0:03:48

0:03:48

0:03:48

0:03:48