filmov

tv

Machine Shop Basics: Selecting Dial Indicators for the Machine Shop

Показать описание

A lot of beginners have been asking questions about what kind of dial indicators they should be looking for to use in the machine shop. In this video, I will discuss some of the basic types of dial indicators and what kinds you might or might not need to get started with.

Machine Shop Basics: Selecting Dial Indicators for the Machine Shop

Getting Started In Machining - Absolute Beginners Click Here!

Metal Lathe Tutorial 11 : How To Buy And Use Indicators

I Bought A Minimill to see if they are Worth It

Different Types of Dial Indicator Bases - Quick Machining Tips #25

Machining process #5 #cnc #machine #tools

How to choose the right tool holder for your CNC Machine | DN Solutions

Picking up an Edge with an Indicator

HSN | C. Wonder Christian Siriano Fashions 01.09.2025 - 02 PM

Import Lathe Buying Guide

Tips to Select the Right Milling Cutter | Machine Shop Talk Ep. 5

Indicator Basics - Using a Test Indicator - Haas Automation, Inc.

Cheap Way to Measure Very Accurately!

Milling Machine fundamentals - Tramming your vice

All You REALLY Need to Know About Mini Mills

VMC MACHINE TOOL CHANGE || VMC MACHINE TOLL CHANGE KAISE KARE .

ALL MEASURING INSTRUMENTS LEAST COUNT

Machine Shop Basics: Setting up a Vise on a Milling Machine

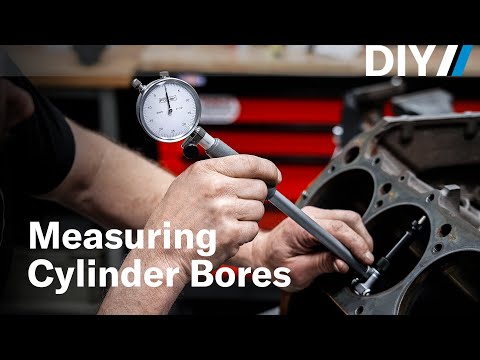

Measuring cylinder bores using a dial bore gauge | DIY

Vertical Mill Tutorial 2 : Setup

Tool and Die Engineering

Tools, Glorious Tools! #4 - Setting Up A Home Machine Shop: Where Do I Start?

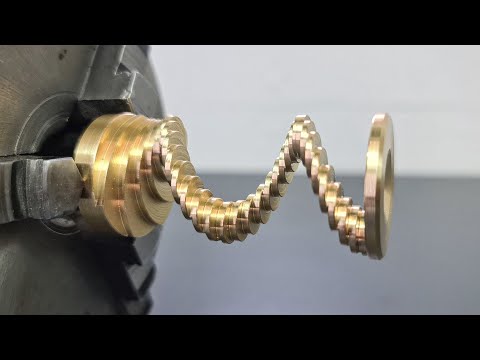

Making a Crazy Part on the Lathe - Manual Machining

Lathe Tool Shapes - What Are They All For?

Комментарии

0:21:45

0:21:45

0:28:21

0:28:21

0:11:19

0:11:19

0:08:03

0:08:03

0:07:34

0:07:34

0:00:46

0:00:46

0:10:34

0:10:34

0:17:00

0:17:00

1:00:00

1:00:00

0:27:33

0:27:33

0:11:15

0:11:15

0:05:19

0:05:19

0:07:00

0:07:00

0:03:50

0:03:50

0:14:42

0:14:42

0:00:31

0:00:31

0:01:20

0:01:20

0:05:43

0:05:43

0:09:11

0:09:11

0:17:17

0:17:17

0:00:16

0:00:16

0:10:31

0:10:31

0:04:15

0:04:15

0:29:15

0:29:15