filmov

tv

Corrugated Metal Panels vs. Standing Seam Metal Roofing | Roofing Mythbusters Series - Episode #4

Показать описание

Let’s talk METAL. Roofing expert Luke Wilson looks at the pros and cons of 29-gauge corrugated metal panels vs. 24-gauge standing seam metal roofing, and explains how a properly-installed standing seam roof will last you a lifetime.

Corrugated Metal Panels vs. Standing Seam Metal Roofing | Roofing Mythbusters Series - Episode #4

Standing Seam Metal Roofing Vs Corrugated Screw Down Metal Roof - Big Differences between the Two

Standing Seam Metal Roof Vs Corrugated Metal Roofing [Cost + Pros & Cons + Installation]

Types Of Metal Roofing Panels. Standing Seam, Corrugated, R Panel: Which Style Is Right For You?

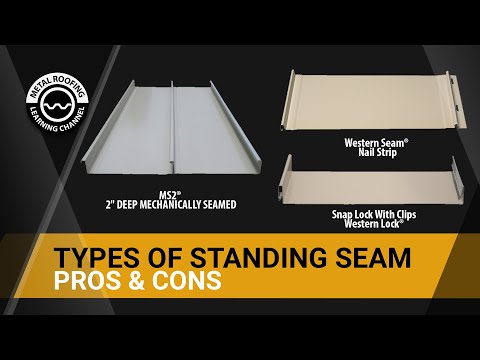

Which Is The Best Type Of Standing Seam Metal Roof? Snaplock Vs Mechanically Seamed Vs Nail Strip

Corrugated Metal Roofing Panels: Pros And Cons + Cost. Is Corrugated Roofing Right For Your House?

Types of Corrugated Metal Roofing, Siding, Wall Panels: Which Is The Best Exposed Fastener Panel?

8 Types of Metal Siding And Metal Wall Panels: Which Is Right For Your House?

Black Metal Roofing Panels [Pros, Cons + House Pics] Matte Black Standing Seam And Corrugated Roofs

How Much Does Metal Roofing Cost? 2024 Price Per Square Foot For Standing Seam & Corrugated Meta...

Corrugated Metal Panels vs. Standing Seam Metal Roofing .(Part 1)

Corrugated Metal Panels vs. Standing Seam Metal Roofing . (part 2)

Busting common MYTHS about Metal Roofing!

24-Gauge vs. 26-Gauge Metal Roofing: Which is Better for Your Project?

5 Common Mistakes to Avoid When Installing Metal Roofing

Corrugated - Metal Roofing Must-Knows

Metal Siding: Pros, Cons, And Cost

Nu-Wave® Corrugated Metal Roofing & Siding

4 Types Of Metal Roofing And Siding for Barns. Which Is Best For You?

Standing Seam VS 5V Metal Roofs

Metal Roofing & Siding - Top 10 Reasons to Choose it

Metal Roofing Benefits: 10 Advantages Of A Standing Seam Metal Roof.

Exposed Fastener Vs. Standing Seam Metal Roofing Revisited

🪛📐CREST FITTING SCREWS TO 7/8 CORRUGATED ROOF PANELS #string #line #predrill #screw #diy #roofing...

Комментарии

0:09:27

0:09:27

0:12:40

0:12:40

0:06:43

0:06:43

0:05:31

0:05:31

0:10:17

0:10:17

0:03:52

0:03:52

0:07:48

0:07:48

0:02:50

0:02:50

0:08:43

0:08:43

0:04:56

0:04:56

0:05:27

0:05:27

0:15:08

0:15:08

0:10:21

0:10:21

0:03:29

0:03:29

0:01:47

0:01:47

0:03:39

0:03:39

0:00:32

0:00:32

0:04:52

0:04:52

0:03:37

0:03:37

0:02:48

0:02:48

0:04:22

0:04:22

0:06:38

0:06:38

0:00:30

0:00:30