filmov

tv

Building a DIY Wide Body Kit for my Lamborghini Murcielago

Показать описание

In todays episode we're 3d printing a custom wide bodykit or my Lamborghini Murcielago sema build.

Huge thanks to creality for providing us with the 3d printers, if youre in the market for a 3d printer be sure to check them out!

Music:

Fareoh - Cloud Ten

Building a DIY Wide Body Kit for my Lamborghini Murcielago

Building a DIY Wide Body Kit for my Mid Engine 67 Ford Mustang Fastback

DIY Widebody M3: Part 1

DIY BODY KIT DURING QUARANTINE

10 Easy Steps to a Widebody - A Complete DIY Tutorial

DIY Widebody Overfender Pt.1 | The Foam

DIY Racecar Mold and Fiberglass Fabrication (Build Your Own Aero)

FRS / BRZ Rocket Bunny DIY Over Fender Comprehensive Install Guide

DIY Carbon Fiber Widebody Kit Part 2 | Rabbit Build Ep2

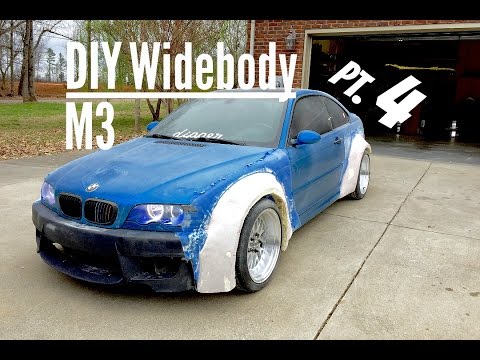

DIY Widebody M3 Pt 4

DIY GT40 SUPERCAR | #TOYOTIRES | [4K60]

Finishing Our INSANE 300ZX DIY Widebody Kit (WIDER THAN A LAMBORGHINI)

DIY Custom Carbon Fiber Flares

Is This A DIY Body-Kit?! | From The Gallery EP.65

Installing An INSANE DIY WIDEBODY Kit On Our Ugly Nissan 300ZX (EARL LEEKER IS BACK!)

DIY Widebody M3: Part 2 Wheels and Shaping

DIY Widebody M3 Pt. 3

Budget DIY Lip Kit with Garden Edging

This New Mod Will Add 400 Horsepower to Your Car

DIY Widebody M3 Pt 14 Passenger Side Is DONE!

DIY Wire rolled edge crimping tool, body work, making a widebody. widebody kit, overfenders

How to Make Carbon Car Bonnet/Hood. A simple DIY version anyone can do. Easy Composites. ep.31

THE C7 WIDEBODY POWERWHEELS pt. 6: DIY DEEP DISH WHEELS

How to make DIY carbon fiber parts at home with wet lay

Комментарии

0:29:03

0:29:03

0:27:09

0:27:09

0:16:01

0:16:01

0:09:03

0:09:03

0:40:16

0:40:16

0:07:48

0:07:48

0:17:54

0:17:54

0:12:37

0:12:37

0:06:46

0:06:46

0:20:29

0:20:29

0:08:27

0:08:27

0:13:05

0:13:05

0:29:16

0:29:16

0:11:59

0:11:59

0:23:14

0:23:14

0:12:59

0:12:59

0:16:18

0:16:18

0:11:10

0:11:10

0:10:16

0:10:16

0:13:08

0:13:08

0:07:53

0:07:53

0:21:00

0:21:00

0:11:55

0:11:55

0:07:38

0:07:38