filmov

tv

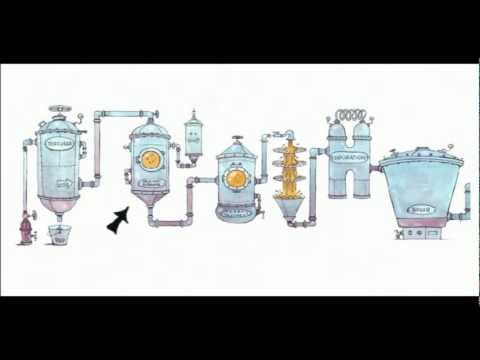

How It's Made: Beet Sugar

Показать описание

Stream Full Episodes of How It's Made:

Subscribe to Science Channel:

Like us on Facebook:

Follow us on Twitter:

Follow us on Instagram:

Subscribe to Science Channel:

Like us on Facebook:

Follow us on Twitter:

Follow us on Instagram:

How It's Made: Beet Sugar

How Sugar Is Made From Sugar Beets | Sugar Beet Harvesting & Processing | Sugar Factory

How it's Made - Beet Sugar

How Is Beet Sugar Processed?

How is SUGAR Made from Beets? Amazing Sugar Making Process!

How Sugar Is Made | How It's Made

SUGAR | How It's Made

Making Home Made Sugar From Beets/ Is It Worth It?

Experience the Zesty Fusion of Yuzu and Miso #japanesefood

White Sugar Doesn’t Come From Where You Think It Does

How to Make Sugar From Beets

Making Sugar/Molasses Out Of Sugar Beets.

Small Scale Beet Sugar Production Methods

From beet to sugar | Cosun Beet Company [English - EN subtitles]

Sugar made from UK sugar beet.

How It's Made: Sugar

Sugar beet Cultivation (Complete Information) | How Sugar is Made? | Sugar beet Farming

Is Beet Sugar Healthy? Learn More About This White Sugar Alternative

Where does sugar come from?

The History of Sugar Beets

Making Sugar | from | Sugar Beets | Our First Time Making Sugar From Sugar Beets

The Process Of Making Cane Sugar #satisfying #short

How BEET SUGAR is made? From harvest to production!

How sugar is made from sugar beet? #sugarbeet #sugarglider

Комментарии

0:05:25

0:05:25

0:08:40

0:08:40

0:03:48

0:03:48

0:01:16

0:01:16

0:08:57

0:08:57

0:07:32

0:07:32

0:07:55

0:07:55

0:15:15

0:15:15

0:00:43

0:00:43

0:18:55

0:18:55

0:02:32

0:02:32

0:06:37

0:06:37

0:10:56

0:10:56

0:04:00

0:04:00

0:02:17

0:02:17

0:08:35

0:08:35

0:03:18

0:03:18

0:03:02

0:03:02

0:00:39

0:00:39

0:05:34

0:05:34

0:19:23

0:19:23

0:00:15

0:00:15

0:07:21

0:07:21

0:00:41

0:00:41