filmov

tv

GD&T Lesson 2: Form Tolerances

Показать описание

This is the second video in a series of GD&T lessons.

I cover Flatness, Straightness, Circularity and Cylindricity.

At minute 10:50 there is a mistake, the gage would be 1.05, not 1.06 like I say in the video.

00:00 Introduction

01:10 Straightness

08:14 Flatness

10:54 Circularity

13:44 Cylindricity

I cover Flatness, Straightness, Circularity and Cylindricity.

At minute 10:50 there is a mistake, the gage would be 1.05, not 1.06 like I say in the video.

00:00 Introduction

01:10 Straightness

08:14 Flatness

10:54 Circularity

13:44 Cylindricity

GD&T Lesson 2: Form Tolerances

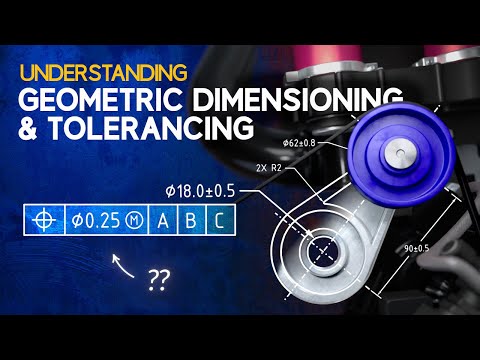

Understanding GD&T

Form Tolerances

GD&T example: 2 parts with datums, position, and profile tolerance

Form tolerance in GD&T

Reading GD&T Drawings Step by Step

[GD&T Introduction Course] Lesson 2 - What is Geometry, Dimension & Tolerance [In English]

GD&T Part 2 Profile Tolerances - Understanding Geometric Dimensioning and Tolerancing

GDT Form Tolerance Part 1 Straightness and Flatness

Full GD&T - Profile Tolerancing

How to Apply GD&T Position Tolerance to a Hole

GD&T Basics - Flatness

GD&T - Form Tolerance & DimXpert on Drawings

Summary of How GD&T Works

NeuroMeasure5 - Introduction of GD&T, and Form Tolerance

xavier memes #memes

GD&T - DimXpert Orientation Tolerances

GD&T: Profile vs Flatness

GD&T ASME Y14.5 Coplanarity Tolerances. Size, Form, Orientation and Profile

GDT Form Tolerance Part 2 Roundness and Cylindricity

GD&T (Geometric Dimensioning & Tolerance) in AutoCAD #tolerance #gdtsymbols #autocad

GD&T Position vs Concentricity – Comparison

GD&T Lesson 6: Profile Tolerances

MMC and LMC, Rules 1 and 2 of GD&T, Bonus Tolerance

Комментарии

0:15:10

0:15:10

0:29:32

0:29:32

0:05:16

0:05:16

0:05:07

0:05:07

0:00:22

0:00:22

0:08:25

0:08:25

![[GD&T Introduction Course]](https://i.ytimg.com/vi/MQ3yGo593NM/hqdefault.jpg) 0:16:00

0:16:00

0:08:13

0:08:13

0:19:13

0:19:13

0:04:44

0:04:44

0:03:16

0:03:16

0:17:07

0:17:07

0:08:02

0:08:02

0:06:23

0:06:23

0:07:44

0:07:44

0:00:06

0:00:06

0:16:07

0:16:07

0:07:03

0:07:03

0:06:55

0:06:55

0:14:31

0:14:31

0:00:27

0:00:27

0:07:48

0:07:48

0:26:13

0:26:13

0:37:46

0:37:46