filmov

tv

Thin-Walled PRESSURE VESSELS in 8 MINUTES - Mechanics of Materials

Показать описание

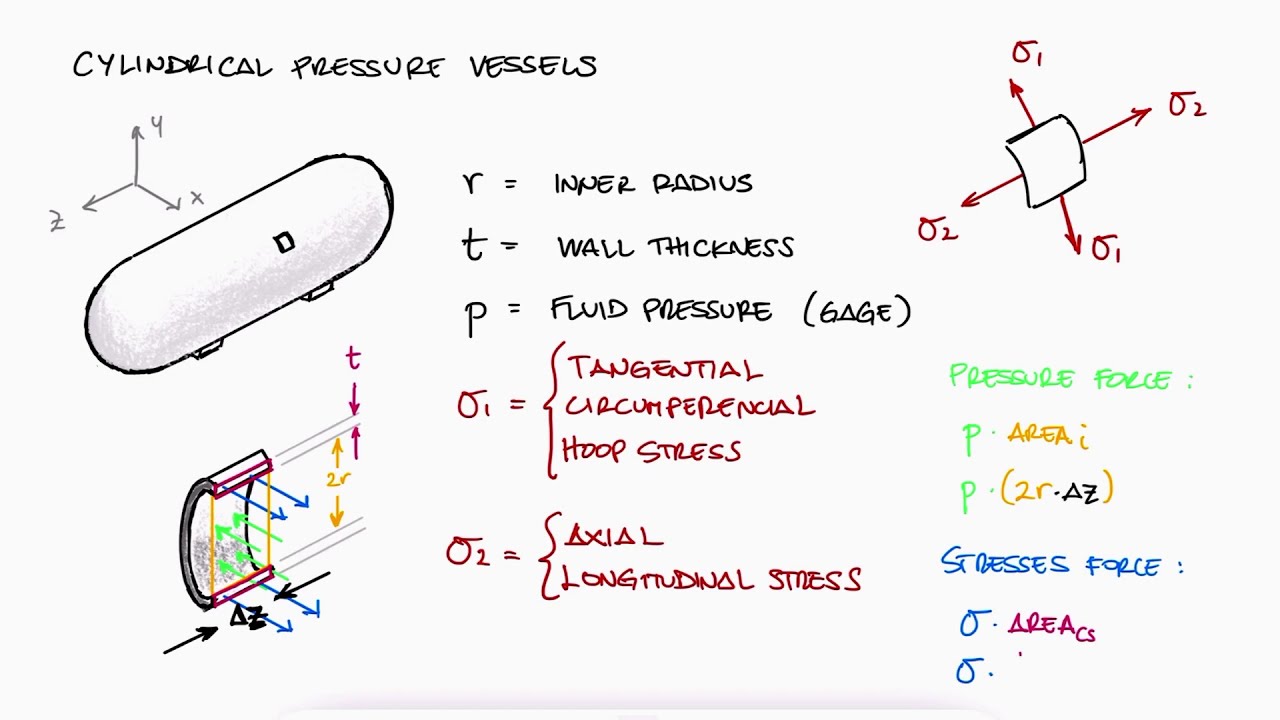

Hoop Stress (tangential, circumferential), Longitudinal Stress (axial), and more!

0:00 Pressure Vessels Stresses

0:40 Dimensions Nomenclature

0:59 Hoop Stress (Cylindrical)

2:02 Longitudinal Stress

2:48 Spherical Vessel Stresses

3:50 Principal Stresses

4:14 Cylindrical Principal Stresses

5:28 Spherical Principal Stresses

6:33 Pressure Vessel Example

__________________________________________________________

Previous Main Video Link:

Principal Stresses and MOHR'S CIRCLE in 12 Minutes!!

Next Main Video Link:

Yield (DUCTILE) Failure Theories in Just Over 10 Minutes!

______________________________________________________________

Other Mechanics of Materials Lectures:

Watch the entire course in less than 4 HOURS!!

20 Elastoplastic Beams and Residual Stresses (torsion too): coming soon

0:00 Pressure Vessels Stresses

0:40 Dimensions Nomenclature

0:59 Hoop Stress (Cylindrical)

2:02 Longitudinal Stress

2:48 Spherical Vessel Stresses

3:50 Principal Stresses

4:14 Cylindrical Principal Stresses

5:28 Spherical Principal Stresses

6:33 Pressure Vessel Example

__________________________________________________________

Previous Main Video Link:

Principal Stresses and MOHR'S CIRCLE in 12 Minutes!!

Next Main Video Link:

Yield (DUCTILE) Failure Theories in Just Over 10 Minutes!

______________________________________________________________

Other Mechanics of Materials Lectures:

Watch the entire course in less than 4 HOURS!!

20 Elastoplastic Beams and Residual Stresses (torsion too): coming soon

Thin-Walled PRESSURE VESSELS in 8 MINUTES - Mechanics of Materials

Mechanics of Materials: Lesson 41 - Intro to Thin Walled Pressure Vessels

[A55] MEC 32 Lesson 6: Thin-walled Pressure Vessels (1/3)

CYLINDRICAL Pressure Vessel Stresses in Under 2 Minutes!

07.1 Thin walled pressure vessels

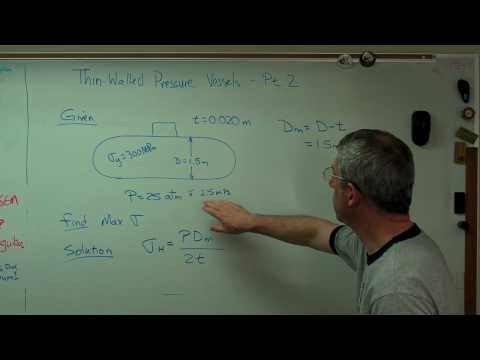

Thin Wall Pressure Vessel 2.MP4

Thin-Walled Pressure Vessels

The Aluminum Beverage Can - Thin Walled Pressure Vessel

Understanding The Basics of Thin-Walled Pressure Vessels

Mechanics of Materials: Lesson 42 - Thin Walled Pressure Vessel Example Problem

Thin Walled Pressure Vessel – Part 2 (Data Acquisition).

Lecture 8a thick and thin walled pressure vessels

Materials Science Thin Walled Cylindrical Pressure Vessels

SPHERICAL Pressure Vessel in Under 2 Minutes!

Thin Walled Pressure Vessel Problem: Stress and Strain Tensors In A Copper Pipe

Mechanics of Materials | Thin walled Pressure Vessels | Solved Example 5| Filament wound PV

(20AA) Thin-walled pressure vessels

Statics and Mechanics | Thin-Wall Pressure Vessels

thin-walled pressure vessels example

Lecture 9: Thin Walled Pressure Vessel Strain Gauge Shunt Calibration Example Problem

Maximum Internal Pressure in Cylindrical PRESSURE VESSEL in 80 Seconds!

ENGR 216 Lecture 22: Comb. Loading [cont'd] & Thin-Walled Pressure Vessels (2016.11.15)

Mechanics of Materials | Thin walled Pressure Vessels | Solved Example 3

Module 4: Hoop Stress - Mechanics of Materials II: Thin-Walled Pressure Vessels and Torsion

Комментарии

0:08:17

0:08:17

0:09:31

0:09:31

![[A55] MEC 32](https://i.ytimg.com/vi/oXst7O7Gh9A/hqdefault.jpg) 0:16:01

0:16:01

0:01:35

0:01:35

0:08:39

0:08:39

0:09:41

0:09:41

0:07:38

0:07:38

0:02:15

0:02:15

0:04:03

0:04:03

0:11:10

0:11:10

0:04:33

0:04:33

0:02:45

0:02:45

0:09:51

0:09:51

0:01:36

0:01:36

0:11:09

0:11:09

0:11:52

0:11:52

0:08:07

0:08:07

0:48:11

0:48:11

0:03:14

0:03:14

0:10:17

0:10:17

0:01:21

0:01:21

1:00:43

1:00:43

0:09:16

0:09:16

0:03:03

0:03:03