filmov

tv

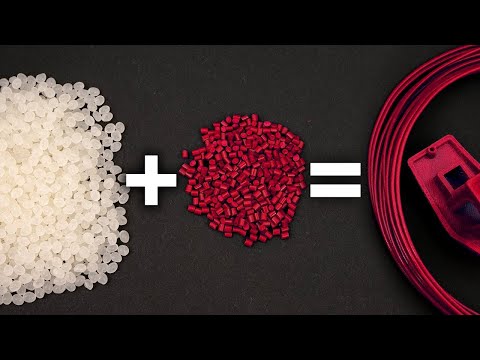

Extruding PLA Filament at Home

Показать описание

I'm starting another journey into filament-making. In the first video of this series, I'm extruding my own PLA filament in different colors using the 3DEVO Desktop Filament Extruder.

💚 Support me 💚

Join as a YouTube member!

🛒 Equipment used in this video:

More affordable "maker" extruders:

🎥 Related videos:

📖 Further Links:

⚙ My gear (Affiliate Links):

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

Chapters

00:00 Introduction

01:17 Extrusion Material

02:10 Extruding Clear PLA

05:52 Extruding Red PLA

08:22 Extruding Sparkly Blue Filament

09:34 Recycling failed prints

10:31 Pricing and target audience

11:51 Squarespace Integration

13:14 Summary

#3Dprinting #filament #DIY

DISCLAIMER: This video was sponsored by Squarespace.

Extruding PLA Filament at Home

Recycling Failed 3D Prints with a DIY Filament Extruder: Artme3D

Make Your Own Filament At Home? My Review of the FelFil Evo Filament Extruder

S25 Desktop Filament Extruder - A Year Later

Recycle your failed 3D prints! Make new filament at home.

Make Your Own Filament at Home: Take 2 - 3DEVO COMPOSER First Impressions

How to Make free & easy filament for 3D printer at home

Recycling all my 3DBenchys into new Filament

Fix Your Ender 3 3D Printer

FIXstruder filament making machine / filament extrusion machine

How It Is Made: 3D Printing Filament

How to Extrude 3D Printer Filament (Basics of Screw Extrusion)

How to make 3D printer filament with a lab extruding machine

PLA filament extrusion machine

3D Printing is SLOW?| FLSUN V400

3D Print your own Dual Extrusion (2 colors at once) Filament!!

3D printing filament extruding machine

3D printing filament extruding machine

How NOT to build a Filament Extruder

My 3D printer is an artist

3D printer filament extrusion machine Part 02

Extruding Blue 3D Printer Filament from homemade plastic extruder

Home use mini 3D printer filament extrusion line - lab. Filament making machine

Stop 3d printing so slow!!! 🤯 (how to print faster)

Комментарии

0:14:04

0:14:04

0:20:10

0:20:10

0:22:55

0:22:55

0:04:24

0:04:24

0:09:03

0:09:03

0:14:30

0:14:30

0:07:44

0:07:44

0:15:18

0:15:18

0:00:25

0:00:25

0:01:09

0:01:09

0:04:56

0:04:56

0:35:20

0:35:20

0:00:16

0:00:16

0:00:11

0:00:11

0:00:55

0:00:55

0:00:59

0:00:59

0:00:08

0:00:08

0:00:15

0:00:15

0:14:12

0:14:12

0:00:36

0:00:36

0:00:13

0:00:13

0:00:36

0:00:36

0:00:43

0:00:43

0:04:14

0:04:14