filmov

tv

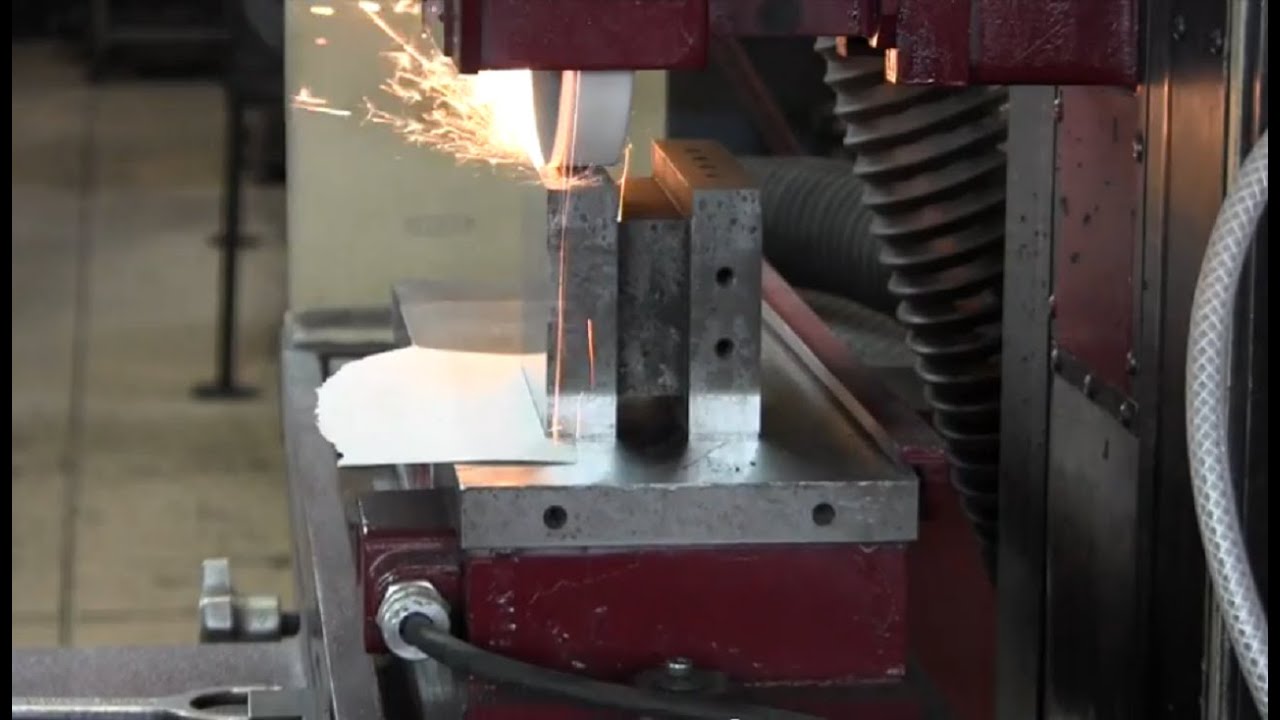

How To Square a Part within .0001 on a Surface Grinder

Показать описание

Here are some creative ways to shim without traditional shim stock.

How To Square a Part within .0001 on a Surface Grinder

Stock? Mill? Square!

How to make square stock straight, smooth and square (stock preparation part 1) | Paul Sellers

Clever way to indicate a square part in a 4 jaw chuck - SUPER EASY !!

How to square any piece of wood using only a table saw and a straight board

Development of a square to square transition piece using triangulation

Square Holes - 5 Methods To Make Them in Metal

How To Square A Roof. EASY Step By Step Video [3,4,5 Triangle Method To Install Metal Roofing]

How to Square Lumber with a Jointer | Woodworking

Spare Parts #13 - Making A Square Broach

Solve by completing the square | Step by Step Technique

GCSE Maths - How to Factorise Quadratics by Completing the Square (Part 1 - Factorise When a=1)

Solving Quadratic Equations By Completing The Square

How to Plane Narrow Board Edges Square | Paul Sellers

GCSE Maths - How to Solve a Quadratic by Completing the Square (Part 2 - Solve When a=1)

How to Square, Flatten, & Dimension Rough Boards by Hand

How to Square Fabric

How to make flat boards straight, smooth and square (stock preparation part 2) | Paul Sellers

Pocket Square - One Point

few know the trick of cutting a square tube for a 90 degree joint with precision results

How to fold POCKET SQUARE under 15 seconds!

How to Use a Speed Square Part 2

How to Approximate Square Root of a Number

How to Divide a Square into Fifths

Комментарии

0:16:33

0:16:33

0:25:16

0:25:16

0:30:30

0:30:30

0:06:15

0:06:15

0:02:30

0:02:30

0:12:35

0:12:35

0:13:46

0:13:46

0:02:40

0:02:40

0:04:40

0:04:40

0:08:21

0:08:21

0:05:20

0:05:20

0:05:14

0:05:14

0:07:57

0:07:57

0:05:24

0:05:24

0:03:37

0:03:37

0:28:58

0:28:58

0:07:56

0:07:56

0:43:11

0:43:11

0:00:13

0:00:13

0:05:18

0:05:18

0:00:14

0:00:14

0:11:25

0:11:25

0:00:52

0:00:52

0:04:27

0:04:27