filmov

tv

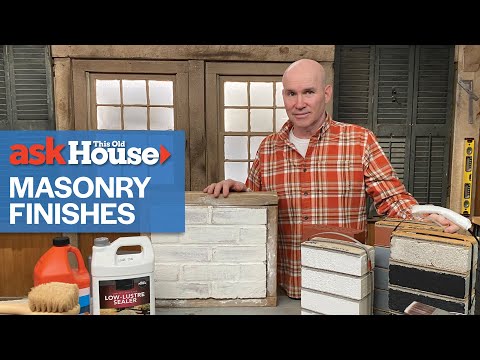

Watch this before doing Brick or Masonry

Показать описание

Follow along behind the scenes at -

Huge thanks to our Show sponsors Polywall, Huber, Dorken Delta, Prosoco, Rockwool & Viewrail for helping to make these videos possible! These are all trusted companies that Matt has worked with for years and trusts their products in the homes he builds. We would highly encourage you to check out their websites for more info.

Комментарии