filmov

tv

How to Identify a Forged Anvil

Показать описание

Everything you need to know to identify what type of anvil you have found!

Enjoy EC? Join Essential Craftsman Academy!

This is the best way to support Essential Craftsman and you get a LOT of perks as a bonus!

Check it out.

Did you know we have a podcast?

If you are going to hire a contractor for a big project PLEASE read our ebook first!

Amazon Affiliate Links:

Video Equipment and Misc.

Learn more about Essential Craftsman

Thank you, be safe, and be grateful

Enjoy EC? Join Essential Craftsman Academy!

This is the best way to support Essential Craftsman and you get a LOT of perks as a bonus!

Check it out.

Did you know we have a podcast?

If you are going to hire a contractor for a big project PLEASE read our ebook first!

Amazon Affiliate Links:

Video Equipment and Misc.

Learn more about Essential Craftsman

Thank you, be safe, and be grateful

How to Identify a Forged Anvil

How can you tell a forged document from an authentic one? We asked the experts for help

How to spot a forged signature using 3D Imaging! - foster+freeman VSC

Have you ever forged someone’s signature? #forging #signature #crime

How to recognize a Forged Signature! (theory + practice)

How to tell a cast crankshaft from a forged. Easy way to identify forged steel crankshafts from cast

What are the common signs of a forged signature?

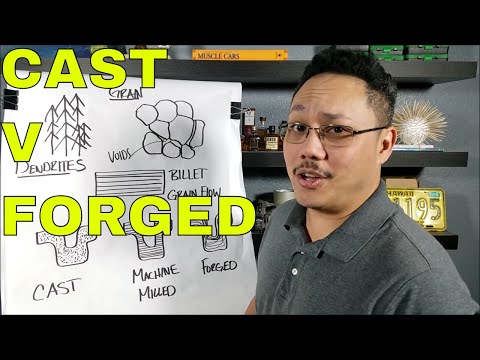

CAST VS FORGED PARTS WHY CAST IS BAD AND WHY FORGED IS BETTER

Cast vs Forged Irons: What's The Difference?

Cast vs Flow-Formed vs Forged: What's The Difference?

How To Tell The Difference Between A Cast And Forged Crankshaft… The Easy Way! #shorts

How can I prove someone forged my signature?

Someone Forged Your Name on a Check

Can you prove the signature was forged?

£50 Polymer Bank Note Security Features How To Spot A Fake / Forged / Counterfeit Polymer £50 GBP UK...

How To Find a Forged Crankshaft for your Turbo 07K build

Forgery and forged documents: methods, types. Signature forgery and its examination

How We Forged A Real Carbon Steel Katana

Any guesses what this forged piece is for? If you’ve been following my channel you already know 😉...

Are these 7 signatures genuine or forged ?

Altered v Forged Checks

Forged in Fire: 5 Things Everyone Should Know About Weapon Making (S1, E2) | History

Altered document cut and paste signatures forged onto a contract

Rookie Bladesmith Nearly Faints! | Forged in Fire (Season 1)

Комментарии

0:08:56

0:08:56

0:03:28

0:03:28

0:00:59

0:00:59

0:00:20

0:00:20

0:06:30

0:06:30

0:03:30

0:03:30

0:03:09

0:03:09

0:04:16

0:04:16

0:01:23

0:01:23

0:03:31

0:03:31

0:00:59

0:00:59

0:00:52

0:00:52

0:03:43

0:03:43

0:02:15

0:02:15

0:03:01

0:03:01

0:06:47

0:06:47

0:30:00

0:30:00

0:00:21

0:00:21

0:00:22

0:00:22

0:01:33

0:01:33

0:05:38

0:05:38

0:01:39

0:01:39

0:06:38

0:06:38

0:08:53

0:08:53