filmov

tv

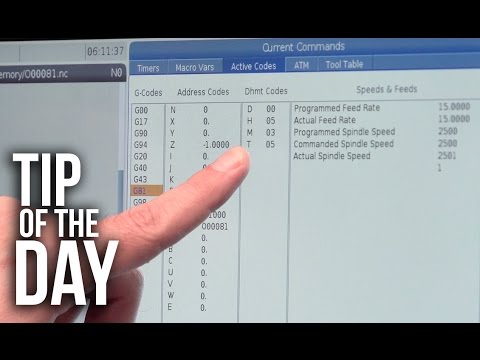

Shorten Your G-Code Using a WHILE Loop! | CNC Macro Programming Tutorial

Показать описание

@GCodeTutor demonstrates how to remove a large amount of material writing only 9 lines of G-code.

As we saw in other videos in this series of CNC programming tutorials, Macro B variables are a great way to simplify your G-code programs and make them easier to read and modify.

In this video, Marc Cronin shows how to write a Macro program using a WHILE loop.

Stay tuned for more machining videos!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Recommended CNC programming books:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Practical Machinist is the largest and most engaged metalworking community across the web. With more than 160,000 registered members and 300,000+ social media followers, Practical Machinist is the easiest way to learn new techniques, get answers quickly, and discuss common challenges with your peers. Visit Practical Machinist today to join the community and start connecting with your peers.

#Gcode #CNCprogramming #macroprogramming

As we saw in other videos in this series of CNC programming tutorials, Macro B variables are a great way to simplify your G-code programs and make them easier to read and modify.

In this video, Marc Cronin shows how to write a Macro program using a WHILE loop.

Stay tuned for more machining videos!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Recommended CNC programming books:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Practical Machinist is the largest and most engaged metalworking community across the web. With more than 160,000 registered members and 300,000+ social media followers, Practical Machinist is the easiest way to learn new techniques, get answers quickly, and discuss common challenges with your peers. Visit Practical Machinist today to join the community and start connecting with your peers.

#Gcode #CNCprogramming #macroprogramming

Shorten Your G-Code Using a WHILE Loop! | CNC Macro Programming Tutorial

Knowing what code is used here can be called a master #CNC lathe #turn-milling #CNC programming

Machinist Trick to NOT Break Tools

G74 in CNC | What is G90 in Fanuc | #simulator #boringOperations #groove_ing operation #shortvideo

Advanced CNC macro programming using G-Code - learn CNC

Create custom M or G codes

Reduce setup times without having to know G-code or macro programming.

CNC Macro Programming Tutorial: IF Statements

Secret Art of MACRO PROGRAMMING on a CNC Machine | G-Code Genius

Tips to Speed Up G-Code Programming

THESE G-CODE SHORTCUTS Will Speed Up Your Programming Process SIGNIFICANTLY

PathPilot Quick Tips: Finding a Specific Line in G-Code

Hack #9 Two color prints

G-code Path Conflict Detection

G-Code tutorial - Avoiding Obstacles Using G98 and G99 Codes

G code loop programming example machining 2x72 belt grinder.

What is G-Code? – Haas Automation Tip of the Day

Auto Convert G Code Between #Fanuc / #Okuma and #HaasCNC Formats in Seconds

I and J explained for 2444 Manual CNC Programming

Easy Chords For Beginners

Automate #GCode Editing / Reduce #CNCMachine Downtime / Enhance Your #CADCAM and #CNCProgramming

G Code - NC file size reduction - Mastercam - Fusion 360

How to change the Z-seam in Cura Slicer!

The Differences between G codes and M codes

Комментарии

0:06:14

0:06:14

0:00:19

0:00:19

0:00:58

0:00:58

0:00:16

0:00:16

0:01:08

0:01:08

0:04:40

0:04:40

0:00:28

0:00:28

0:05:33

0:05:33

0:12:03

0:12:03

0:08:27

0:08:27

0:07:29

0:07:29

0:00:43

0:00:43

0:00:29

0:00:29

0:00:39

0:00:39

0:05:33

0:05:33

0:04:45

0:04:45

0:06:17

0:06:17

0:00:21

0:00:21

0:07:18

0:07:18

0:00:09

0:00:09

0:00:29

0:00:29

0:10:05

0:10:05

0:00:52

0:00:52

0:00:57

0:00:57