filmov

tv

Comparing Steel and Fiberglass Rebar - SURPRISING results

Показать описание

Welcome back to The Build Show! In this episode, we dive into the fascinating world of rebar with our engineer Witt Smith, comparing traditional steel rebar to the innovative glass fiber reinforced polymer (GFRP) rebar, specifically the MST bar.

We start by comparing the weight of GFRP rebar to steel. You'll discover that GFRP rebar is significantly lighter, making it much easier to handle on job sites. This difference in weight can improve efficiency and reduce strain on workers.

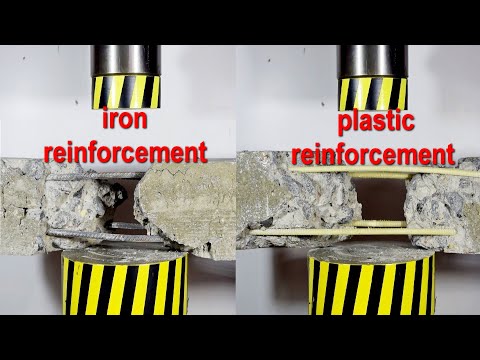

Next, we delve into the material properties of fiberglass rebar. Unlike steel, GFRP rebar has a higher tensile strength and bonds more effectively to concrete. This results in enhanced durability and performance of the reinforced structures.

Worker safety is a major consideration, especially in hot climates. Weitzman explains how GFRP rebar stays cooler in the sun compared to steel, reducing the risk of burns and the need for heavy gloves. This aspect makes GFRP a safer choice for construction crews.

We also discuss the design differences when switching from steel to fiberglass rebar. Our engineer explains how the change in material properties requires adjustments in the design process. It is crucial to incorporate these changes early in the project planning stages to avoid costly redesigns later.

Rust prevention is another significant advantage of GFRP rebar. Traditional steel rebar can rust over time, causing concrete structures to spall and degrade. GFRP rebar, on the other hand, is resistant to rust, making it ideal for use in areas prone to moisture and salt exposure.

In terms of cost, we explain that while GFRP rebar may not always result in immediate savings on smaller projects, it can be cost-effective on larger scales. The long-term benefits of reduced maintenance and increased longevity also contribute to its overall value.

Finally, we highlight the potential applications of GFRP rebar and the importance of early planning in incorporating new materials into your projects. Proper planning ensures that the benefits of GFRP rebar are fully realized.

Stay connected with us for more insights and updates. Follow our 24-part series on the Reisinger Build project to see this and other innovative materials in action. Don't forget to subscribe to our channel for new content every Tuesday and Friday, and stay updated by following us on Facebook and Instagram.

Join us as we explore the future of construction materials and techniques. Let's build smarter and safer together!

MSTBAR

Risinger Build

Subscribe and follow my Podcast on Apple or Spotify!

Sign up for our twice-weekly newsletter:

To sponsor a video or advertise with us visit:

Huge thanks to our Show sponsors Builders FirstSource, Polyguard, Huber, Rockwool & Viewrail for helping to make these videos possible! These are all trusted companies that Matt has worked with for years and trusts their products in the homes he builds. We would highly encourage you to check out their websites for more info.

We start by comparing the weight of GFRP rebar to steel. You'll discover that GFRP rebar is significantly lighter, making it much easier to handle on job sites. This difference in weight can improve efficiency and reduce strain on workers.

Next, we delve into the material properties of fiberglass rebar. Unlike steel, GFRP rebar has a higher tensile strength and bonds more effectively to concrete. This results in enhanced durability and performance of the reinforced structures.

Worker safety is a major consideration, especially in hot climates. Weitzman explains how GFRP rebar stays cooler in the sun compared to steel, reducing the risk of burns and the need for heavy gloves. This aspect makes GFRP a safer choice for construction crews.

We also discuss the design differences when switching from steel to fiberglass rebar. Our engineer explains how the change in material properties requires adjustments in the design process. It is crucial to incorporate these changes early in the project planning stages to avoid costly redesigns later.

Rust prevention is another significant advantage of GFRP rebar. Traditional steel rebar can rust over time, causing concrete structures to spall and degrade. GFRP rebar, on the other hand, is resistant to rust, making it ideal for use in areas prone to moisture and salt exposure.

In terms of cost, we explain that while GFRP rebar may not always result in immediate savings on smaller projects, it can be cost-effective on larger scales. The long-term benefits of reduced maintenance and increased longevity also contribute to its overall value.

Finally, we highlight the potential applications of GFRP rebar and the importance of early planning in incorporating new materials into your projects. Proper planning ensures that the benefits of GFRP rebar are fully realized.

Stay connected with us for more insights and updates. Follow our 24-part series on the Reisinger Build project to see this and other innovative materials in action. Don't forget to subscribe to our channel for new content every Tuesday and Friday, and stay updated by following us on Facebook and Instagram.

Join us as we explore the future of construction materials and techniques. Let's build smarter and safer together!

MSTBAR

Risinger Build

Subscribe and follow my Podcast on Apple or Spotify!

Sign up for our twice-weekly newsletter:

To sponsor a video or advertise with us visit:

Huge thanks to our Show sponsors Builders FirstSource, Polyguard, Huber, Rockwool & Viewrail for helping to make these videos possible! These are all trusted companies that Matt has worked with for years and trusts their products in the homes he builds. We would highly encourage you to check out their websites for more info.

Комментарии

0:12:14

0:12:14

0:24:43

0:24:43

0:01:01

0:01:01

0:08:11

0:08:11

0:01:02

0:01:02

0:03:34

0:03:34

0:08:08

0:08:08

0:02:17

0:02:17

0:00:54

0:00:54

0:01:39

0:01:39

0:03:45

0:03:45

0:00:39

0:00:39

0:02:52

0:02:52

0:03:30

0:03:30

0:00:29

0:00:29

0:02:52

0:02:52

0:19:25

0:19:25

0:02:26

0:02:26

0:01:11

0:01:11

0:08:47

0:08:47

0:01:28

0:01:28

0:00:15

0:00:15

0:04:06

0:04:06

0:01:50

0:01:50