filmov

tv

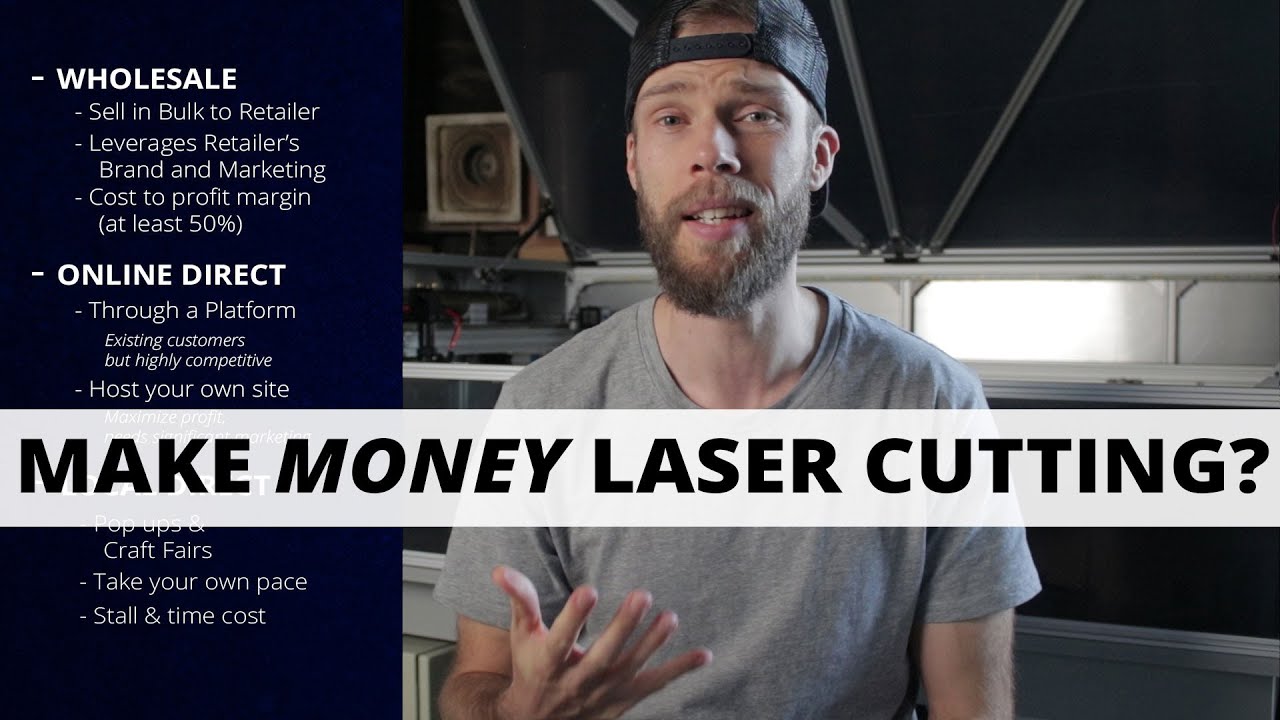

How I Make Money Laser Cutting: A Beginner's Overview

Показать описание

Product Designs and my Laser Cutter Documentation:

Hey everyone! Hope you're all doing ok in these challenging times.

In this video I talk about my experience making money and running a small side business using a laser cutter.

Instagram:

Hey everyone! Hope you're all doing ok in these challenging times.

In this video I talk about my experience making money and running a small side business using a laser cutter.

Instagram:

How To Make Money With A Laser Engraver

How to make money with a laser!

I Tried Starting A Laser Engraving Business In 7 Days

Start making MONEY with a laser $2994 00 in a month!! Easy Laser Cut Project Epilog, Glowforge &...

Make Money With Your Laser, Laser cut lanterns (full tutorial)

9 Easy and Profitable laser engraving products that SELL!!!

5 Easy Laser Engraving Projects That Sell FAST

Crushing Financial Goals: How I Paid Off My Laser in Just 90 Days!

Making Diode laser key fobs for money

How I Make Money Laser Cutting: A Beginner's Overview

How to Make Money with a Laser: Sales Tips, Laser Project Ideas, & More (xTool P2 CO2 Laser Mach...

Start A Laser Business NOT On Etsy! Think Services!

Make This With Your Laser To Leave Your Day Job

Discover How You Can Make Money With a Laser Engraver - Top 10 Ways

7 Reasons To Start A Laser Engraving Side Hustle In 2023 - Make Money With a Laser Engraver

How to Make Money Making Wall Art with a Cheap Desktop Laser

How To Make Easy Money With A Laser Engraver - Acrylic Edge Lit Signs!

How to Make Money with Your Laser - White Tile Method

How I make MONEY on Etsy with a Laser Engraver

How to MAKE MONEY with a Laser Engraver!

Making Money with a Laser Engraver - Top 5 Items that SELL! Featuring the AlgoLaser Alpha 22W!

How to make MONEY on your Co2 Laser for beginners - OMTech 60w -

25 Products That Let Me Quit My Full-Time Job

Inside My Laser Business | Financials, Tips and Lessons Learned

Комментарии

0:08:25

0:08:25

0:11:42

0:11:42

0:08:01

0:08:01

0:08:01

0:08:01

0:20:43

0:20:43

0:16:05

0:16:05

0:08:18

0:08:18

0:25:11

0:25:11

0:06:05

0:06:05

0:14:36

0:14:36

0:14:49

0:14:49

0:19:04

0:19:04

0:16:11

0:16:11

0:09:44

0:09:44

0:07:29

0:07:29

0:18:06

0:18:06

0:07:23

0:07:23

0:10:52

0:10:52

0:05:11

0:05:11

0:19:31

0:19:31

0:11:53

0:11:53

0:06:57

0:06:57

0:08:29

0:08:29

0:16:45

0:16:45