filmov

tv

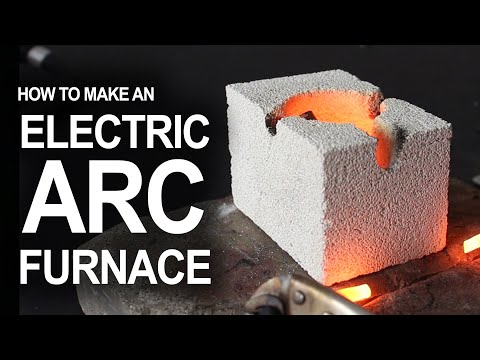

Aluminum Casting with Microwave Transformer - No Induction Heater

Показать описание

Learn how to cast aluminum at home using a simple DIY induction heater! In this video, we'll guide you through the process of building a powerful induction heater using a microwave transformer. We'll cover everything from the basics of transformer working principles to the intricacies of aluminum melting and casting.

Key topics covered:

Transformer Basics: Understand how transformers work and their role in induction heating.

DIY Induction Heater: Build a simple and effective induction heater using readily available components.

Aluminum Melting: Learn the optimal techniques for melting aluminum using induction heating.

Casting Process: Explore different casting methods and tips for creating high-quality aluminum castings.

Safety Precautions: Prioritize safety by learning about potential risks and preventive measures.

Join us on this exciting DIY journey and unlock the world of metalworking!

20%OFF Coupon Code for Hammer drill::BG7322

PLAYLISTS :

#aluminum #casting #transformer #inductionheater #aluminumcasting #mrelectron

Key topics covered:

Transformer Basics: Understand how transformers work and their role in induction heating.

DIY Induction Heater: Build a simple and effective induction heater using readily available components.

Aluminum Melting: Learn the optimal techniques for melting aluminum using induction heating.

Casting Process: Explore different casting methods and tips for creating high-quality aluminum castings.

Safety Precautions: Prioritize safety by learning about potential risks and preventive measures.

Join us on this exciting DIY journey and unlock the world of metalworking!

20%OFF Coupon Code for Hammer drill::BG7322

PLAYLISTS :

#aluminum #casting #transformer #inductionheater #aluminumcasting #mrelectron

Комментарии

0:11:48

0:11:48

0:00:39

0:00:39

0:10:32

0:10:32

0:35:29

0:35:29

0:00:39

0:00:39

0:05:15

0:05:15

0:18:30

0:18:30

0:13:02

0:13:02

0:13:59

0:13:59

0:00:42

0:00:42

0:11:48

0:11:48

0:07:41

0:07:41

0:00:16

0:00:16

0:08:07

0:08:07

0:01:01

0:01:01

0:13:03

0:13:03

0:06:21

0:06:21

0:01:45

0:01:45

0:02:29

0:02:29

0:00:49

0:00:49

0:01:14

0:01:14

0:04:42

0:04:42

0:05:13

0:05:13

0:04:31

0:04:31