filmov

tv

EXPLAINED: How a Hydrostat Transmission Works

Показать описание

I show how a hydrostatic transmission drive unit works on a John Deere 2320 HST compact utility tractor. This unit had a drive-shaft u-joint failure which broke the input shaft to the hydrostatic drive transmission.

The hydrostatic drive is divided into two portions, a variable flow pump controlled by a swash plate, and a fixed ratio hydraulic drive motor.

The forward / reverse speed of the tractor is controlled by foot pedals, which are connected by linkage to the swash plate in the drive pump. This controls the direction and flow rate of hydraulic fluid sent to the hydraulic drive motor.

The hydraulic drive motor is forced to turn in either direction based on the flow rate and direction of the hydraulic fluid. The motor will also hydro-lock on the fluid when there is no flow, causing the drive motor to also work as a brake.

If you have one of these JD 2320 tractors, be sure to check your driveshaft u-joints and keep them greased!

The hydrostatic drive is divided into two portions, a variable flow pump controlled by a swash plate, and a fixed ratio hydraulic drive motor.

The forward / reverse speed of the tractor is controlled by foot pedals, which are connected by linkage to the swash plate in the drive pump. This controls the direction and flow rate of hydraulic fluid sent to the hydraulic drive motor.

The hydraulic drive motor is forced to turn in either direction based on the flow rate and direction of the hydraulic fluid. The motor will also hydro-lock on the fluid when there is no flow, causing the drive motor to also work as a brake.

If you have one of these JD 2320 tractors, be sure to check your driveshaft u-joints and keep them greased!

EXPLAINED: How a Hydrostat Transmission Works

How Does a Hydrostatic Transmission Work?

Hydrostatic vs Gear Drive Tractors

Closed Loop Hydrostatic Drive - An Inside Look!

How Hydrostatic Transmission⚙️ 👀#cad #machine #engineering #gear #auto #engine #1ksubscribers...

Hydrostatic Transmission System

Hydraulic Oil Pressure and Transmission System 🚜

Hydrostatic Transmission Operation - Pt. 1

How to: Driving a Kubota L Series Tractor – Homestead Vlog Ep. 5

Hydrostatic Transmission systems explanation (sort of)

Cat® Medium Wheel Loader XE Advanced Powertrain Explained

Torque Converter, How does it work?

HYDROSTATIC TRANSMISSION SYSTEM (5TH & 7TH SEMESTER DEGREE ENGINEERING, HGCE, VAHELAL)

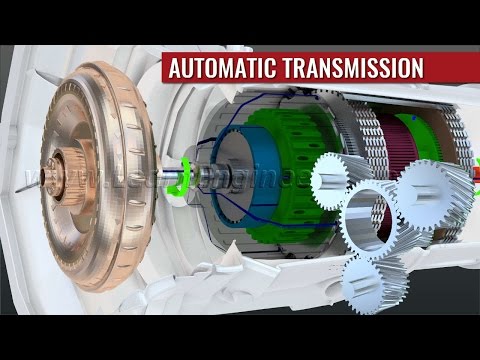

Automatic Transmission, How it works?

Learn the Differences of Hydrostat Transmissions from Massey Ferguson

How hydrostatic transmissions make crawler dozers more versatile

Making a Hydrostatic Transmission Last Longer

Advantages And Disadvantages of Hydrostatic Transmission Systems

Closed Loop (Hydrostatic) Charge Pressure

Proper use of a Hydrostatic pedal - TMT

Hydrostat vs Mechanical Transmissions

Configurations And Control System of Hydrostatic Transmission Systems

Hydrostatic Transmission Hack For Craftsman, Husqvarna And More

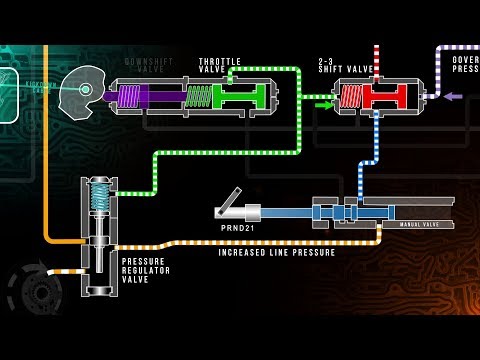

Automatic Transmission Hydraulics Training Module Trailer

Комментарии

0:08:56

0:08:56

0:15:21

0:15:21

0:06:46

0:06:46

0:10:32

0:10:32

0:00:18

0:00:18

0:12:03

0:12:03

0:00:12

0:00:12

0:03:11

0:03:11

0:01:21

0:01:21

0:05:14

0:05:14

0:01:40

0:01:40

0:08:31

0:08:31

0:07:38

0:07:38

0:07:36

0:07:36

0:26:00

0:26:00

0:05:13

0:05:13

0:01:24

0:01:24

0:08:34

0:08:34

0:07:07

0:07:07

0:03:18

0:03:18

0:08:46

0:08:46

0:05:05

0:05:05

0:03:52

0:03:52

0:01:59

0:01:59