filmov

tv

Building A Guitar Body - Making A Guitar From Scratch Part 1

Показать описание

This is the first video in my guitar series. I've built several guitars before, but only from kits. This will be my first guitar built entirely from scratch. I'm literally starting from the tree. This video covers how I made the body. Stay tuned for more!

Building A Guitar Body - Making A Guitar From Scratch Part 1

Ep 1 - Guitar Design and Body Shaping - The Uncut Kit Guitar Build

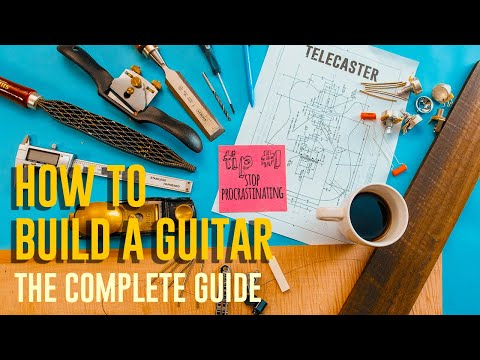

Watch this BEFORE you build a GUITAR!

How to Build a Guitar Body Using Templates | Pine Guitar Body

How To Build Your First Guitar : the ULTIMATE GUIDE FOR NON WOODWORKERS

Making a CUSTOM guitar: The OPAL (Full BUILD)

Making a Telecaster Style Guitar Body with Templates (Woodshop #asmr)

I Built an Acoustic Guitar with Electric Guitar Body Size - Full Build

Building a Psaltery (Lap Harp, Kantele, Zither)

Building a Guitar Out of 700 Sheets of Newspaper

Handcrafting an Ultra Stratocaster (Full Build & Sound Test)

Making hollow body guitar.

Top 10 (or so) Essential Tools for Building a Guitar at Home

I Built a Guitar Out of Plywood // Great Guitar Build-Off 2020 Unofficial Entry

Build your DREAM GUITAR BODY from SCRATCH for $30!!! (feat. Corey Muxlow of Saul Goode Guitars)

Making A Telecaster Guitar From Scratch

Building a Custom Guitar - Part 2 'Making the Body'

Building my StewMac STRATOCASTER | My New Favorite DIY Guitar Kit

DIY Building a Strat Guitar body Guitar Build Process for a Stratocaster

Ultra Stratocaster Build - Part 1 of 3 (Full Black Limba Body Build)

Does It Make Sense To Build A Guitar?

BUDGET Tele Build! - Building a Killer Guitar That Won't Break the Bank!

Create YOUR OWN CUSTOM GUITAR (On a budget!)

Walnut TELECASTER Build

Комментарии

0:14:55

0:14:55

0:11:22

0:11:22

0:17:36

0:17:36

0:23:06

0:23:06

0:15:00

0:15:00

0:13:52

0:13:52

0:20:01

0:20:01

0:15:34

0:15:34

0:12:50

0:12:50

0:16:14

0:16:14

0:15:52

0:15:52

0:24:20

0:24:20

0:14:48

0:14:48

0:23:24

0:23:24

0:09:09

0:09:09

0:12:24

0:12:24

0:19:48

0:19:48

0:07:38

0:07:38

0:38:26

0:38:26

0:09:51

0:09:51

0:16:23

0:16:23

0:12:19

0:12:19

0:27:32

0:27:32