filmov

tv

Loctite Red & Blue EXTREME Impact Vibration Test

Показать описание

See how Red Loctite 271, Blue Loctite 241, and Loctite Super Glue hold up after being tested in my extreme impact vibration test rig.

@hacksbydad

This video description may contain affiliate links. That means if you make a purchase or sign up for a service after clicking one of my links I may receive a commission, at no extra cost to you. As an Amazon Associate, I earn from qualifying purchases.

Thank you for supporting my channel!

Available at Amazon...

This video is for entertainment purposes. Follow the manufacturer's specifications for torquing or loading bolts for your specific application.

@hacksbydad

This video description may contain affiliate links. That means if you make a purchase or sign up for a service after clicking one of my links I may receive a commission, at no extra cost to you. As an Amazon Associate, I earn from qualifying purchases.

Thank you for supporting my channel!

Available at Amazon...

This video is for entertainment purposes. Follow the manufacturer's specifications for torquing or loading bolts for your specific application.

Loctite Red & Blue EXTREME Impact Vibration Test

Did you know this about Loctite Threadlockers??

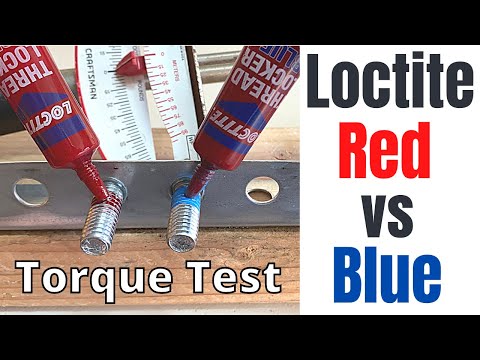

The Honest TRUTH - How Much Stronger is Loctite Red than Loctite Blue?

Correct use of Threadlocker #shorts

Difference Between Red and Blue Loctite #shorts

Most DIYers Do Not Know This | Loctite Red Threadlocker Curing

I Bet You Don’t Know this About Loctite

Use Red Loctite they said lol #shorts

Which 'Red' Threadlocker is Best? Let's find out!

Loctite Threadlocker Gel vs Liquid

Loctite Red 271 Threadlocker for Beginners

Testing the Strength of Thread Locker - Red vs Blue vs Super Glue

Should we use Loctite for this?

Loctite Blue 242 Threadlocker for Beginners

comparing red VS blue Loctite along with super glue and JB weld.

This is why you use thread locker #shorts

LOCTITE extreme works well, oh yeah!

Loctite Professional vs Original Super Glue

Which Threadlock To Use On My Motorcycle | Loctite 246 Alternative

Why & Where Should You Use Threadlock On your Bike? | GCN Tech Monday Maintenance

Red Loctite Curing on Nylon

Red Loctite on Cold Fasteners?

extreme All Purpose Glue

apply locķtite to keep the bolt tight #mechanic #tutorial #youtube #mechanics #youtubeshorts #boat

Комментарии

0:06:23

0:06:23

0:00:35

0:00:35

0:03:05

0:03:05

0:00:47

0:00:47

0:00:19

0:00:19

0:05:52

0:05:52

0:04:08

0:04:08

0:00:12

0:00:12

0:09:24

0:09:24

0:02:44

0:02:44

0:03:04

0:03:04

0:06:09

0:06:09

0:00:36

0:00:36

0:03:13

0:03:13

0:06:47

0:06:47

0:00:18

0:00:18

0:00:59

0:00:59

0:00:53

0:00:53

0:09:53

0:09:53

0:05:53

0:05:53

0:03:03

0:03:03

0:03:35

0:03:35

0:01:37

0:01:37

0:00:12

0:00:12