filmov

tv

Tensile Testing Basics

Показать описание

MTS Application Engineer, Addie Clarke, demonstrates a simple tensile test.

Tensile Testing Basics

Tensile Testing

Tensile Testing Basics | Landmark Servohydraulic System

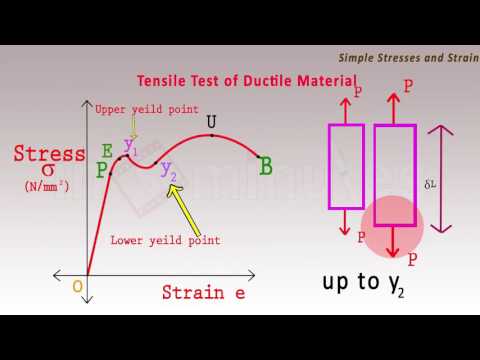

stress strain curve explained with tensile test.

Tensile Test

Metals 101-7 Tensile Testing and the Stress Strain Diagram

Tensile Stress & Strain, Compressive Stress & Shear Stress - Basic Introduction

What is a Universal Testing Machine/Tensile Testing Machine?

QUICK FITTING IN THE MECHANICAL FACTORY (MANUFACTURING AND ASSEMBLING WORKSHOP)

Understanding Material Strength, Ductility and Toughness

Tensile Testing Basics (1)

An Introduction to Stress and Strain

Material Properties 101

ASMR Tensile Test #hydraulicpress #testing #metallurgy #mechanical #materials

Tensile Test

Tensile Testing Basics (2)

Basics of Tensile Testing || Even a Layman can understand || Strength of Materials || Crackit

Yr11 Recap Tensile test basics

Basics of Material Testing, Tensile testing.

Instron® | Learn the Basics of Bluehill® Universal | Webinar

ASTM B557 Aluminum and Magnesium Tensile Testing #materialtesting #tensile

Tensile test diagram (Strength of materials) - Mechanical Engineering

Take a Closer Look at Fatigue & Fracture: Basic Tensile Test

Introduction to Instron® Universal Testing Machines

Комментарии

0:03:17

0:03:17

0:01:28

0:01:28

0:04:37

0:04:37

0:04:22

0:04:22

0:08:59

0:08:59

0:05:50

0:05:50

0:13:05

0:13:05

0:03:51

0:03:51

0:00:13

0:00:13

0:07:19

0:07:19

0:08:14

0:08:14

0:10:02

0:10:02

0:06:10

0:06:10

0:00:08

0:00:08

0:00:06

0:00:06

0:05:05

0:05:05

0:53:12

0:53:12

0:02:22

0:02:22

0:22:18

0:22:18

0:57:30

0:57:30

0:00:39

0:00:39

0:05:33

0:05:33

0:01:43

0:01:43

0:06:11

0:06:11