filmov

tv

Tensile Test

Показать описание

Basic principle and practical procedure of the tensile test on ductile metallic materials

- Testing machine (Inspekt 200 kN, Hegewald & Peschke Meß- und Prüftechnik GmbH), specimen, extensometer

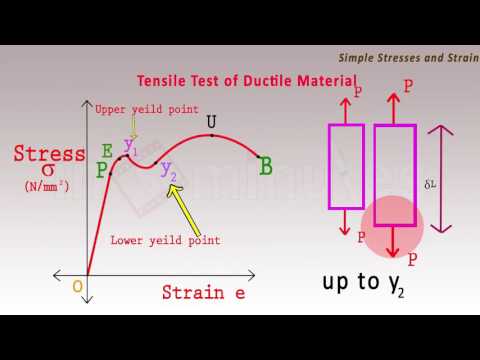

- Material with yield point phenomenon

- Elastic and plastic behaviour, uniform elongation, necking, fracture

- Yield strength, tensile strength, percentage elongation at fracture

- Material without yield point phenomenon

- Plastic behaviour, proof strength

Responsible for this video: Prof. Dr.-Ing. Rainer Schwab, Hochschule Karlsruhe (Karlsruhe University of Applied Sciences), Germany

- Testing machine (Inspekt 200 kN, Hegewald & Peschke Meß- und Prüftechnik GmbH), specimen, extensometer

- Material with yield point phenomenon

- Elastic and plastic behaviour, uniform elongation, necking, fracture

- Yield strength, tensile strength, percentage elongation at fracture

- Material without yield point phenomenon

- Plastic behaviour, proof strength

Responsible for this video: Prof. Dr.-Ing. Rainer Schwab, Hochschule Karlsruhe (Karlsruhe University of Applied Sciences), Germany

Tensile Test

Tensile Testing

Tensile Testing Basics

Tensile Testing a Stainless Steel Tensile Specimen

Understanding Material Strength, Ductility and Toughness

stress strain curve explained with tensile test.

Tensile Test

Tensile test (destructive material testing)

Rebar Tensile Strength Test - Koury Engineering

Metals 101-7 Tensile Testing and the Stress Strain Diagram

Tensile test diagram (Strength of materials) - Mechanical Engineering

ASTM E8 - Violent Break! - Metal Tensile Test Rounded Sample

Tensile test

Tensile Test Definitions

ASMR Tensile Test #hydraulicpress #testing #metallurgy #mechanical #materials

Uniaxial tensile test on stainless steel

Tensile Stress & Strain, Compressive Stress & Shear Stress - Basic Introduction

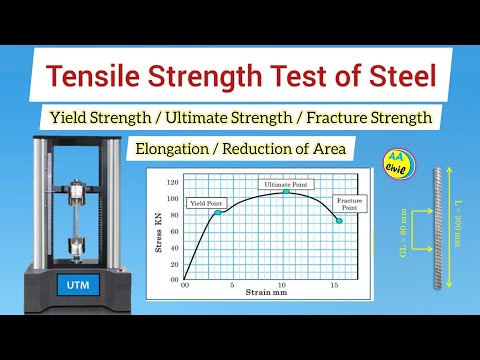

Tensile Strength Test of Steel | Yield Strength | Ultimate Strength | All About Civil Engineer

Tensile Testing of Welded Specimens - ANSI/AWS B4.0 Mechanical Testing of Welds

Ultimate Tensile Strength (UTS) Test Demonstration

What is a Universal Testing Machine/Tensile Testing Machine?

Laboratory Video 2 Tensile Test Steel

The Definitive Guide to Tensile Testing of Plastic to ASTM D638 & ISO 527-2

Tensile Test (Welding Inspector)

Комментарии

0:08:59

0:08:59

0:01:28

0:01:28

0:03:17

0:03:17

0:01:55

0:01:55

0:07:19

0:07:19

0:04:22

0:04:22

0:22:56

0:22:56

0:29:22

0:29:22

0:01:40

0:01:40

0:05:50

0:05:50

0:05:33

0:05:33

0:00:23

0:00:23

0:00:31

0:00:31

0:09:04

0:09:04

0:00:08

0:00:08

0:01:04

0:01:04

0:13:05

0:13:05

0:06:49

0:06:49

0:03:23

0:03:23

0:12:09

0:12:09

0:03:51

0:03:51

0:07:45

0:07:45

0:03:02

0:03:02

0:00:59

0:00:59