filmov

tv

Techniques for Machining Straight Deep Holes -- SHOP GEM --

Показать описание

This video shares some solid techniques that will allow you to drill straighter deeper holes on the lathe and do it with less effort. I'll introduce you to what a diamond pin is, and show you why it works. This one is long, but well worth a look. Check This One Out !!

Techniques for Machining Straight Deep Holes -- SHOP GEM --

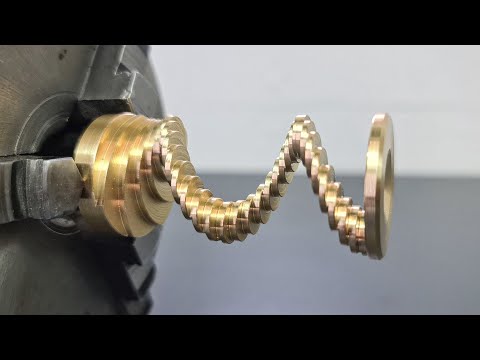

How to process straight knurling?

How to Machine a Straight Mold Insert Chase Pocket – Walls & Floor, Roughing to Finishing

Efficient Spline Broaching Process 🔥🔥

Gun drilling #cncturning #cnclathe #cnc #fanuc #doosan #turning

Cutting grooves with a router and jig #woodworking #joinery #router #festool

ReamMeister - Accelerated deep hole finishing in CNC lathe!

Super stable even in deep hole drilling! #cnc #machine #tools

pipe rolling machine bending

Lathe #lathe #mechanical

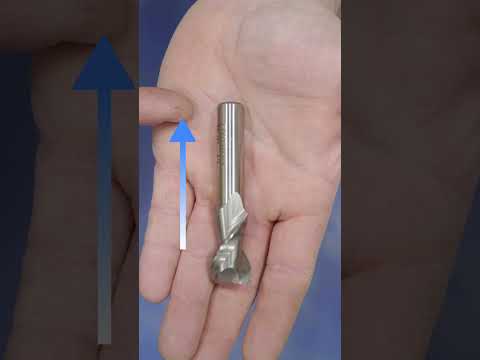

When to Use Spiral vs. Straight Router Bits

Cutting perfect dados the easy way. #diy #router #jig #perfection

Making a Crazy Part on the Lathe - Manual Machining

High-Feed Milling on a Mill-Turn

FixRTurn - Tried interrupted cutting by Round insert.

How to drill straight hole #tipsandtricks #woodworking #diy #smartideas

85% of People Get this Wrong Cutting with a Circular Saw

Basic Router Techniques | Newbie

Straight hole #drill #straight #hole #billa#gadgets #tools #carpenter #tricks #kulwinderbilla

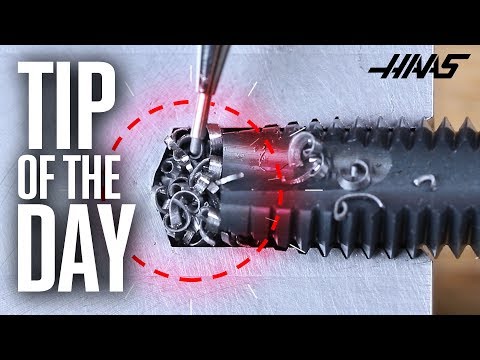

Tapping Essentials - Every Machinist Needs to Watch This - Haas Automation Tip of the Day

Deep Hole Solutions - Gun Drilling

Why no welders talk about this mig welding technique for beginners #sorts #welding

Automatic Straightening machine, straighten deep hole drill bit.#straighteningmachine #drillbit

You NEED to Try this Thread Mill 🔥🔥

Комментарии

0:44:57

0:44:57

0:00:09

0:00:09

0:03:21

0:03:21

0:00:17

0:00:17

0:00:34

0:00:34

0:00:37

0:00:37

0:00:37

0:00:37

0:00:30

0:00:30

0:00:17

0:00:17

0:00:09

0:00:09

0:00:39

0:00:39

0:00:52

0:00:52

0:04:15

0:04:15

0:00:08

0:00:08

0:00:32

0:00:32

0:00:18

0:00:18

0:03:24

0:03:24

0:03:39

0:03:39

0:00:14

0:00:14

0:13:20

0:13:20

0:00:21

0:00:21

0:00:38

0:00:38

0:00:24

0:00:24

0:00:13

0:00:13