filmov

tv

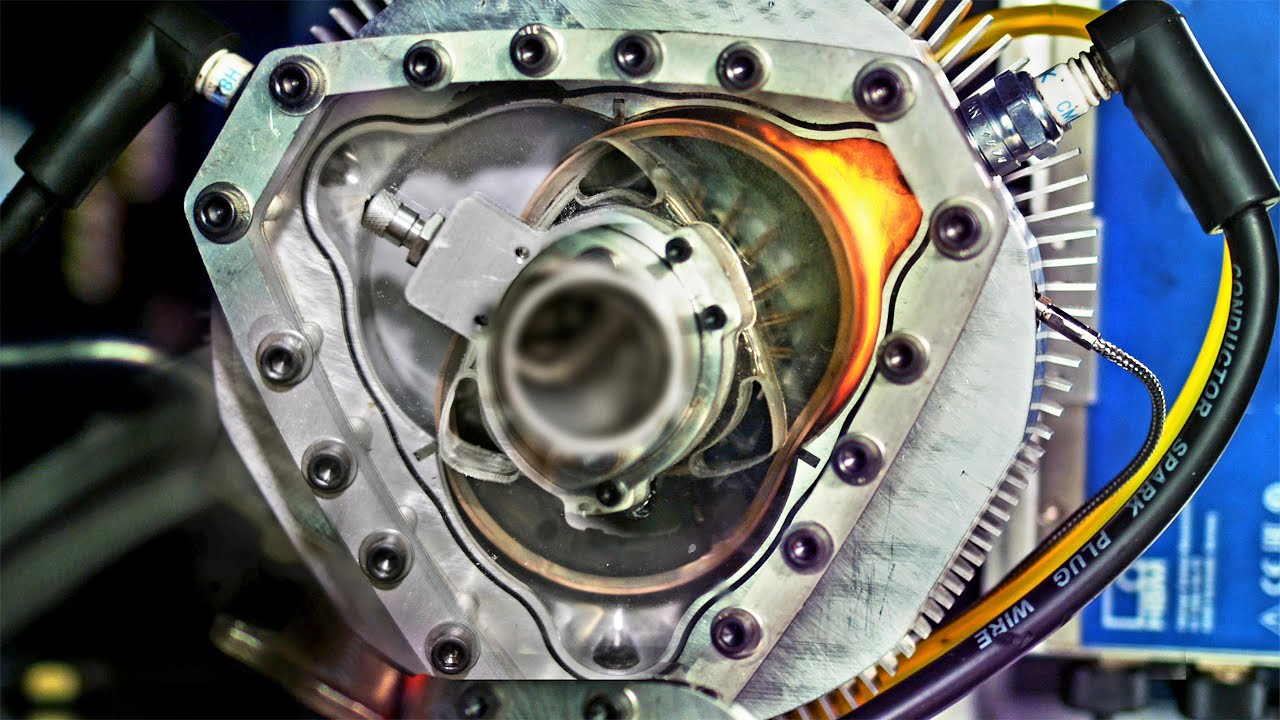

See Thru Liquid Piston Rotary Engine - In Slow Motion

Показать описание

I Run The Liquid Piston Rotary Engine in Slow Motion with all the Inventors and Engineers at LiquidPiston (A Worlds First) to see what is happening inside this new revolutionary Rotary Engine While it's running and how it's so much different than the Wankel Rotary Engine produced by Mazda for the RX7.

This engine reminds me of the Mazda Wankle rotary engine but the difference is it seems like they have solved all of the issues that the Mazda engine had.

I am very excited to see where this engine is going I would love to see this thing powering a car because the power to weight ratio is absolutely insane and the thermal efficiency is out of this world.

definitely check out my other channel for all of the interviews from the inventors and going over the previous versions of this engine.

*Cleared For Public Release

INFO AND LINKS

CHAPTERS

00:00 Intro

00:41 Cutting Parts WaterJet

01:07 Arriving at LiquidPiston

01:26 LiquidPiston Inventors

01:56 How LiquidPiston Works

04:58 See-Thru LiquidPiston Assembled

06:11 1St Run on Propane

07:15 2nd Run On Propane Lights Off

08:29 Run On Acetelyne

09:40 Run on Gasoline

11:10 outro and Follow-Up

↓↓Social media Links↓↓

I sometimes post things early or post previews on FB and Instagram so if you like that sort of thing give them a visit.

Please leave any opinions suggestions or comments Below and don't forget to check out our other videos and subscribe, Thank you.

Watch this in 4k when possible, it looks incredibly awesome !

Carbon 12

Produced By: Carbon 12

Directed By: Matt Mikka

This engine reminds me of the Mazda Wankle rotary engine but the difference is it seems like they have solved all of the issues that the Mazda engine had.

I am very excited to see where this engine is going I would love to see this thing powering a car because the power to weight ratio is absolutely insane and the thermal efficiency is out of this world.

definitely check out my other channel for all of the interviews from the inventors and going over the previous versions of this engine.

*Cleared For Public Release

INFO AND LINKS

CHAPTERS

00:00 Intro

00:41 Cutting Parts WaterJet

01:07 Arriving at LiquidPiston

01:26 LiquidPiston Inventors

01:56 How LiquidPiston Works

04:58 See-Thru LiquidPiston Assembled

06:11 1St Run on Propane

07:15 2nd Run On Propane Lights Off

08:29 Run On Acetelyne

09:40 Run on Gasoline

11:10 outro and Follow-Up

↓↓Social media Links↓↓

I sometimes post things early or post previews on FB and Instagram so if you like that sort of thing give them a visit.

Please leave any opinions suggestions or comments Below and don't forget to check out our other videos and subscribe, Thank you.

Watch this in 4k when possible, it looks incredibly awesome !

Carbon 12

Produced By: Carbon 12

Directed By: Matt Mikka

Комментарии

0:13:31

0:13:31

0:00:50

0:00:50

0:00:51

0:00:51

0:00:08

0:00:08

0:05:09

0:05:09

0:01:00

0:01:00

0:02:28

0:02:28

0:20:17

0:20:17

0:11:34

0:11:34

0:06:51

0:06:51

0:00:16

0:00:16

0:09:12

0:09:12

0:00:32

0:00:32

0:01:11

0:01:11

0:00:23

0:00:23

0:00:35

0:00:35

0:05:38

0:05:38

0:00:59

0:00:59

0:00:04

0:00:04

0:00:28

0:00:28

0:10:31

0:10:31

0:00:24

0:00:24

0:00:39

0:00:39

0:00:07

0:00:07