filmov

tv

Sealing Screws on a Metal Roof - Turbo Poly Seal

Показать описание

See best practices on how to seal screws on a metal roof. This will make your roof leakproof for many years. Anyone can do this.

FTC Affiliate Disclaimer - I get commissions for purchases made through links in this post.

#metalroof #repairs #roofleak

Sealing metal screws on a metal roof is an essential step in preventing leaks and ensuring the longevity of your roof. Here are the steps to follow:

Clean the area around the screws: Use a wire brush or a stiff-bristled brush to clean the area around the screws to remove any dirt, debris, or rust.

Apply a sealant: Apply a high-quality sealant such as Turbo Poly Seal. Be sure to apply enough sealant to completely cover the head of the screws.

Tighten the screws: Use a screw gun to tighten the screws to the manufacturer's recommended torque. Be careful not to over-tighten the screws, which can damage the roof.

Apply a second layer of sealant: Once the screws are tightened, apply a second layer over the screw heads and the area around the screws. This will help ensure a complete seal and prevent water from seeping in.

Inspect the roof: After you have sealed the screws, inspect the roof to ensure no other areas require sealing. If you find any other areas that require sealing, follow the same steps as above to seal them.

By following these steps, you can effectively seal metal screws on a metal roof and prevent any leaks or damage to your roof.

Chapters:

0:00Sealing Screws on a Metal Roof

0:37 Removing loose screws

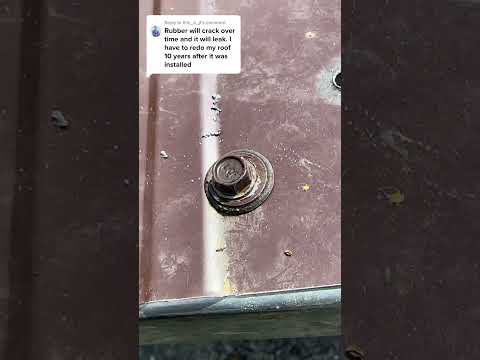

1:59 Cracked washers

2:24 Seal screws with Turbo Poly Seal

3:18 Results after several weeks

FTC Affiliate Disclaimer - I get commissions for purchases made through links in this post.

#metalroof #repairs #roofleak

Sealing metal screws on a metal roof is an essential step in preventing leaks and ensuring the longevity of your roof. Here are the steps to follow:

Clean the area around the screws: Use a wire brush or a stiff-bristled brush to clean the area around the screws to remove any dirt, debris, or rust.

Apply a sealant: Apply a high-quality sealant such as Turbo Poly Seal. Be sure to apply enough sealant to completely cover the head of the screws.

Tighten the screws: Use a screw gun to tighten the screws to the manufacturer's recommended torque. Be careful not to over-tighten the screws, which can damage the roof.

Apply a second layer of sealant: Once the screws are tightened, apply a second layer over the screw heads and the area around the screws. This will help ensure a complete seal and prevent water from seeping in.

Inspect the roof: After you have sealed the screws, inspect the roof to ensure no other areas require sealing. If you find any other areas that require sealing, follow the same steps as above to seal them.

By following these steps, you can effectively seal metal screws on a metal roof and prevent any leaks or damage to your roof.

Chapters:

0:00Sealing Screws on a Metal Roof

0:37 Removing loose screws

1:59 Cracked washers

2:24 Seal screws with Turbo Poly Seal

3:18 Results after several weeks

Комментарии

0:04:03

0:04:03

0:08:28

0:08:28

0:02:36

0:02:36

0:04:06

0:04:06

0:05:43

0:05:43

0:00:57

0:00:57

0:00:25

0:00:25

0:06:23

0:06:23

0:00:51

0:00:51

0:03:09

0:03:09

0:00:26

0:00:26

0:00:56

0:00:56

0:00:17

0:00:17

0:07:36

0:07:36

0:00:53

0:00:53

0:06:31

0:06:31

0:00:56

0:00:56

0:00:39

0:00:39

0:00:41

0:00:41

0:00:35

0:00:35

0:09:32

0:09:32

0:08:33

0:08:33

0:00:15

0:00:15

0:05:03

0:05:03